From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

RECENT POSTS

What Are Pocket Bag Air Filters and How Do You Choose the Right One?

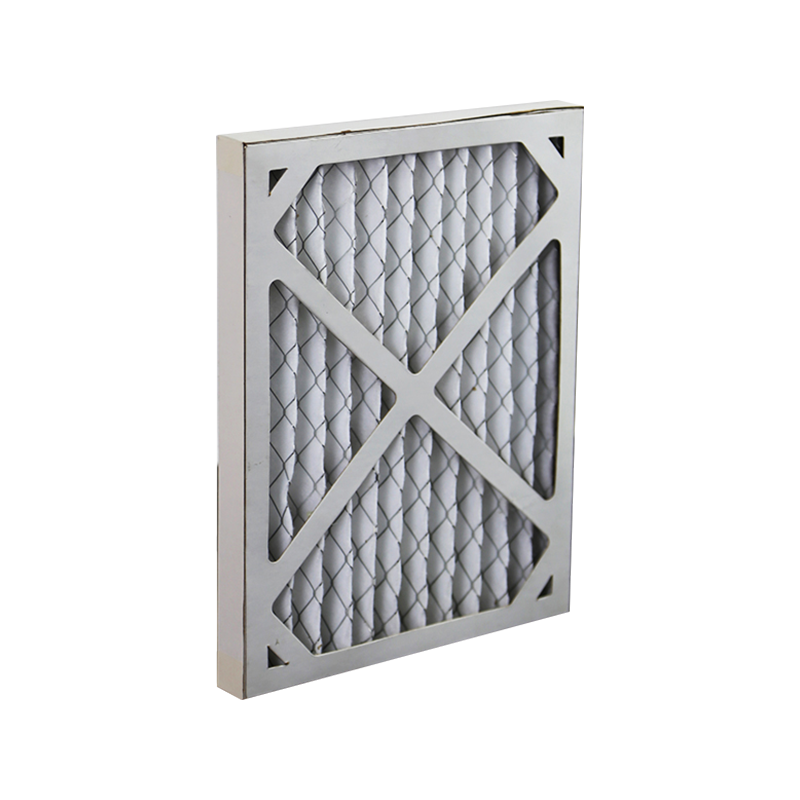

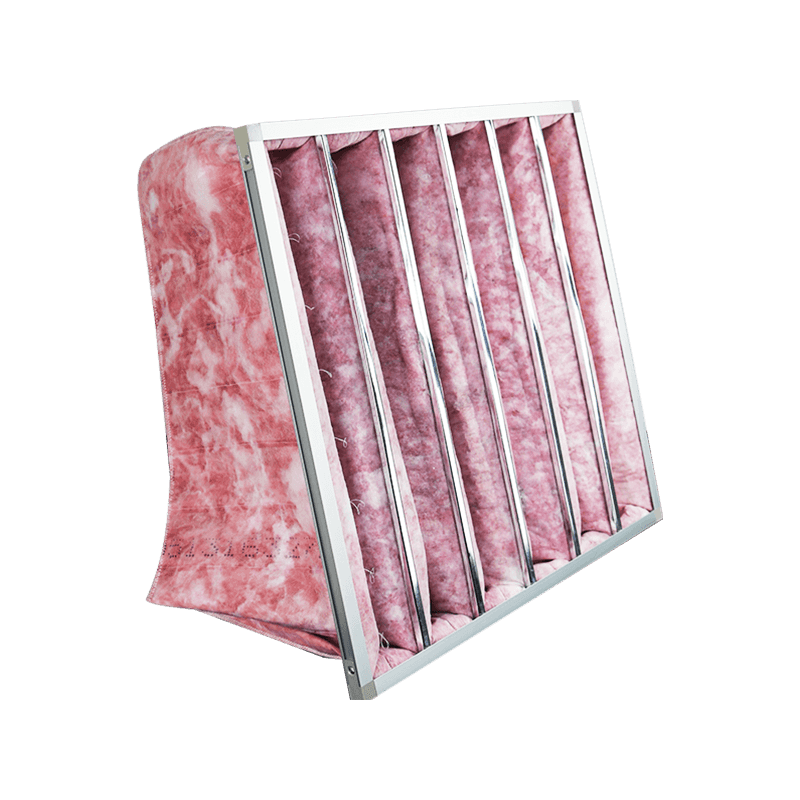

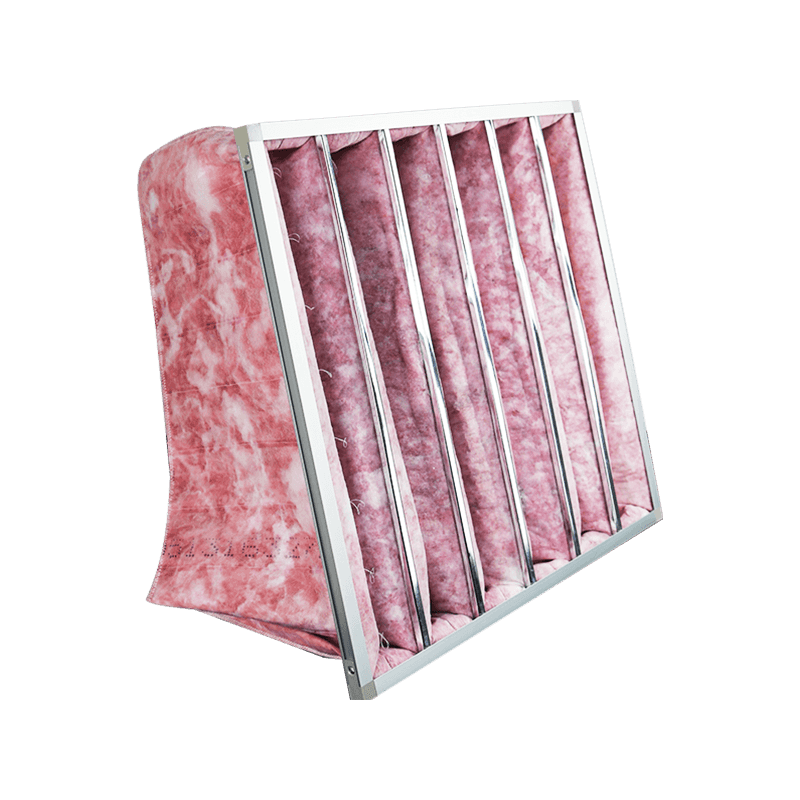

Pocket bag air filters, also known as bag filters or pocket filters, are medium- to high-efficiency air filtration products widely used in HVAC and industrial ventilation systems. Their defining feature is the multi-pocket design, where several flexible filter bags are sewn or welded onto a rigid frame. This structure significantly increases the effective filtration area compared to flat panel filters, allowing higher dust-holding capacity and longer service life.

From a practical standpoint, pocket bag air filters are designed to capture airborne particulate matter such as dust, pollen, fibers, and industrial contaminants while maintaining stable airflow. They are commonly installed as pre-filters or secondary filters to protect downstream equipment and improve indoor air quality.

Working Principle and Filtration Mechanism

Pocket bag air filters operate by forcing air through multiple vertically suspended filter pockets. As air passes through the filter media, particles are captured through a combination of interception, inertial impaction, diffusion, and electrostatic attraction, depending on particle size and filter material.

The pocket configuration ensures that airflow is evenly distributed across the entire filter surface. This reduces localized pressure drops and allows dust to accumulate uniformly, which helps maintain consistent filtration efficiency throughout the filter’s service life.

Common Materials Used in Pocket Bag Air Filters

The performance of pocket bag air filters depends heavily on the filter media and frame materials. Manufacturers select materials based on filtration efficiency, mechanical strength, moisture resistance, and operating temperature.

Typical Filter Media Options

- Synthetic fibers such as polyester or polypropylene

- Glass fiber media for higher temperature resistance

- Multi-layer composite media for improved efficiency

Frames are usually made from galvanized steel, aluminum, or high-strength plastic. The choice of frame affects durability, corrosion resistance, and compatibility with different air handling units.

Efficiency Classes and Industry Standards

Pocket bag air filters are manufactured according to international standards that define their filtration efficiency and performance consistency. The most commonly referenced standards include EN 779 and ISO 16890.

| Standard | Efficiency Class | Typical Application |

| EN 779 | F5–F9 | Commercial HVAC systems |

| ISO 16890 | ePM10 / ePM2.5 / ePM1 | Modern air quality control |

Understanding these classifications helps buyers select pocket bag air filters that meet regulatory requirements and specific indoor air quality targets.

Key Advantages of Pocket Bag Air Filters

One of the primary reasons pocket bag air filters are widely used is their balance between filtration efficiency and energy consumption. The extended surface area allows them to operate at lower pressure drops compared to traditional filters.

- High dust-holding capacity for longer replacement intervals

- Stable airflow and reduced system resistance

- Consistent filtration efficiency over time

- Wide range of sizes and efficiency grades

These advantages make pocket bag air filters a cost-effective choice for facilities aiming to optimize both air quality and operating costs.

Typical Applications and Use Scenarios

Pocket bag air filters are used across many sectors where clean air is essential for comfort, safety, or process reliability. They are commonly installed in air handling units, rooftop HVAC systems, and industrial ventilation lines.

- Commercial buildings such as offices and shopping malls

- Hospitals and healthcare facilities

- Manufacturing plants and clean production areas

- Data centers and equipment rooms

In many systems, pocket bag air filters act as pre-filters that protect high-efficiency filters, extending the overall filtration chain’s lifespan.

Installation and Operational Considerations

Correct installation is essential to ensure pocket bag air filters perform as intended. Filters should be installed with pockets fully extended in the direction of airflow, allowing even dust loading and preventing collapse.

System operators should monitor pressure drop across the filter to determine optimal replacement timing. Replacing filters too early increases costs, while delayed replacement can reduce airflow and strain fans.

How to Select the Right Pocket Bag Air Filter

Selecting the right pocket bag air filter requires evaluating several practical factors, including required efficiency, airflow volume, operating environment, and maintenance strategy. Facilities with high dust loads may benefit from deeper pockets or higher dust-holding designs.

Compatibility with existing filter housings and compliance with local air quality standards should also be confirmed. Working with experienced suppliers helps ensure consistent quality and reliable performance.

Maintenance, Replacement, and Service Life

Pocket bag air filters are designed for extended service life, but regular inspection remains important. Visual checks for damaged pockets, broken seams, or excessive dust buildup help prevent bypass leakage.

Service life varies depending on air quality and system usage, but many pocket bag filters last several months under normal conditions. Proper maintenance planning ensures stable air quality and predictable operating costs.

Conclusion: Practical Value of Pocket Bag Air Filters

Pocket bag air filters offer an effective and economical solution for improving air quality in HVAC and industrial ventilation systems. Their high dust-holding capacity, stable performance, and broad application range make them a preferred choice across many industries.

By understanding materials, efficiency standards, and selection criteria, facility managers and engineers can confidently choose pocket bag air filters that deliver long-term reliability and optimal system performance.

No next article

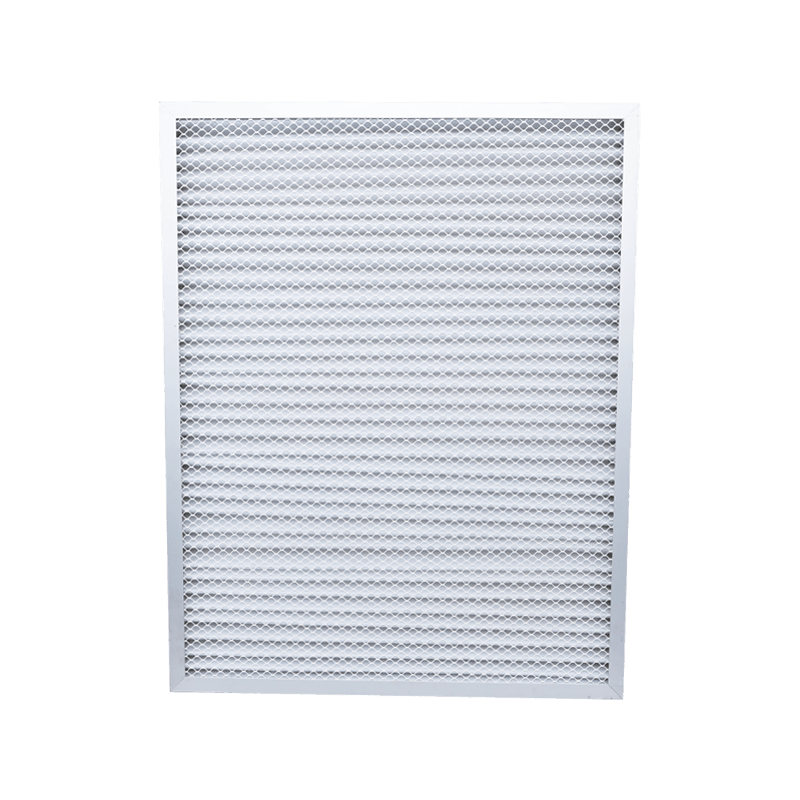

What Are the Benefits of Using Cylindrical High Efficiency Air Filters Compared to Panel Filters?

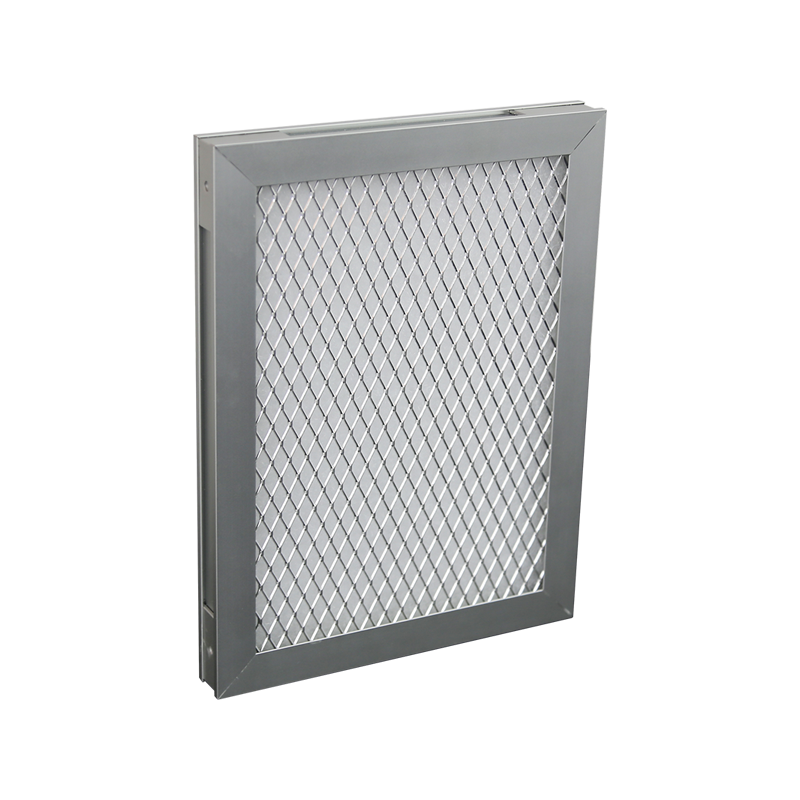

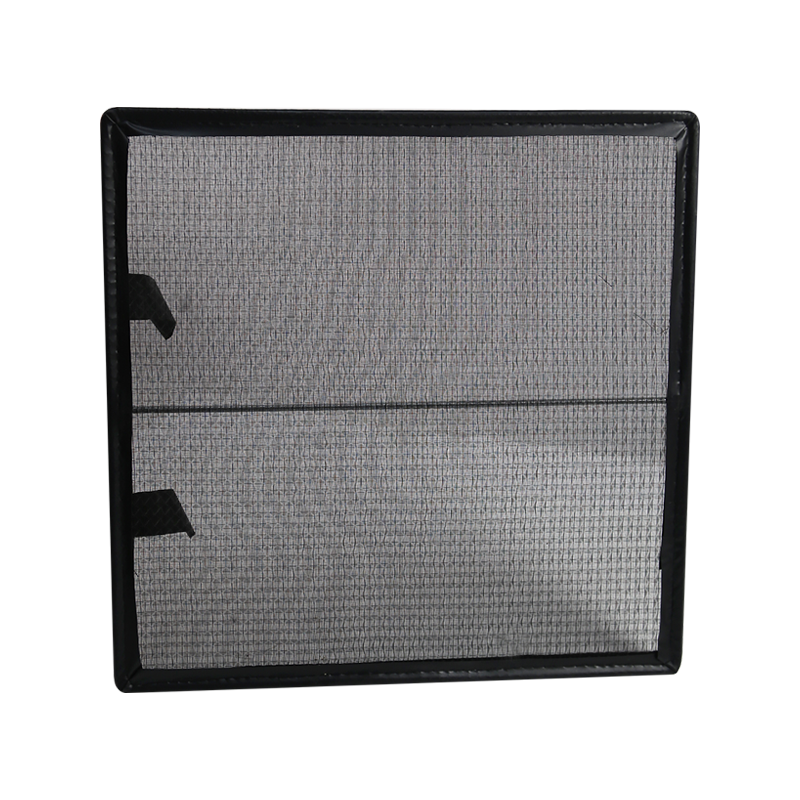

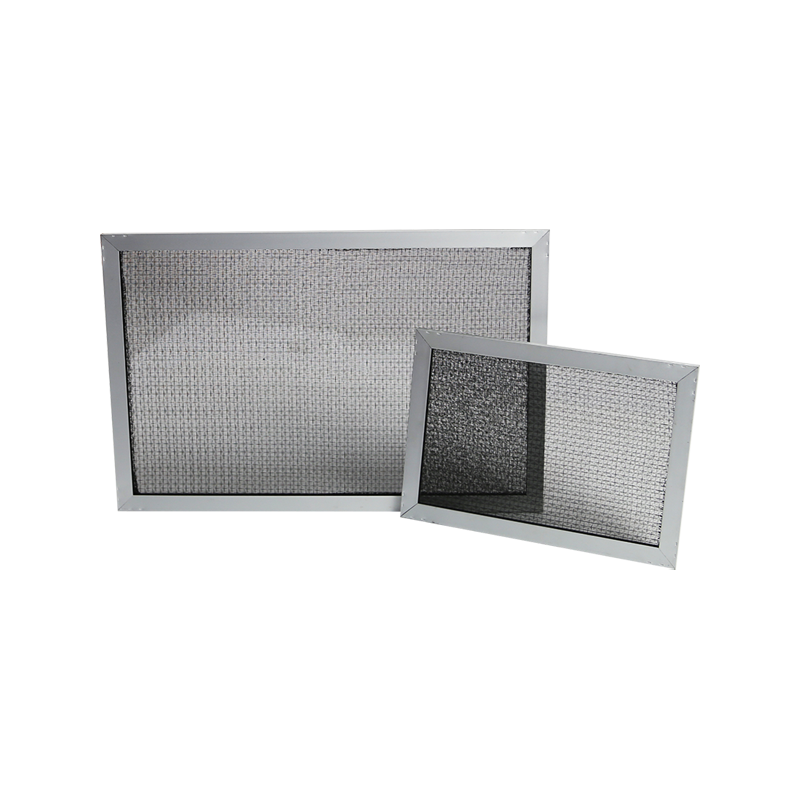

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文