From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

What Are the Benefits of Using Cylindrical High Efficiency Air Filters Compared to Panel Filters?

A cylindrical high efficiency air filter is a depth-style filtration component designed with a round or tubular structure that maximizes usable filter media within a compact footprint. Unlike flat panel filters, cylindrical filters use pleated or layered media arranged around a central core, allowing air to flow through the filter from the outside in or inside out. This structural design significantly increases dust-holding capacity and filtration efficiency while maintaining stable airflow over extended operating periods.

These filters are commonly used in industrial ventilation systems, gas turbines, HVAC units, dust collection systems, clean manufacturing environments, and energy facilities. Their design aligns with applications where high airflow, low pressure drop, and long service life are critical performance requirements.

What Defines a Traditional Panel Filter

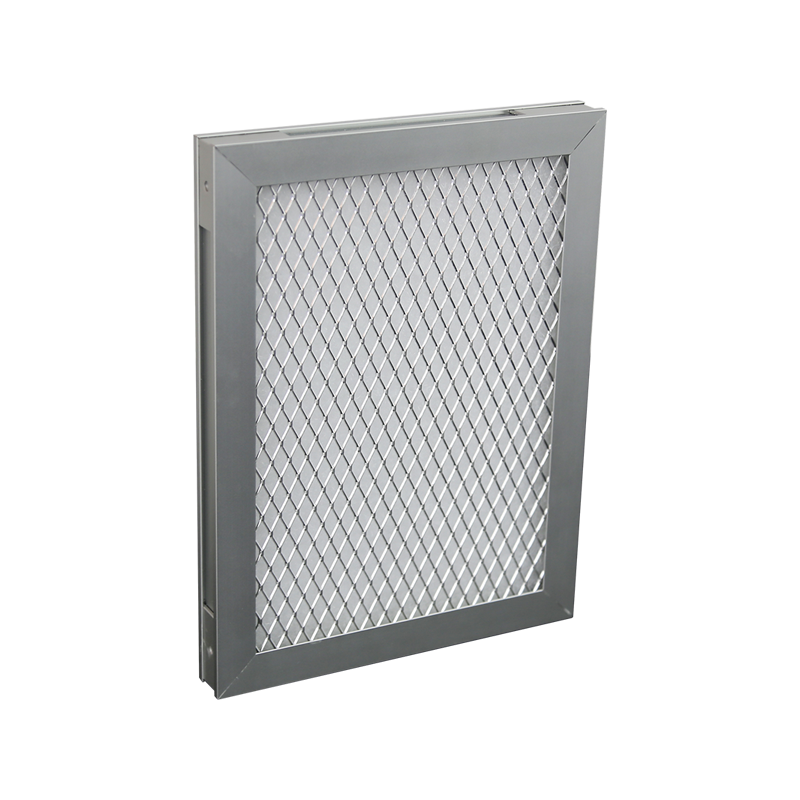

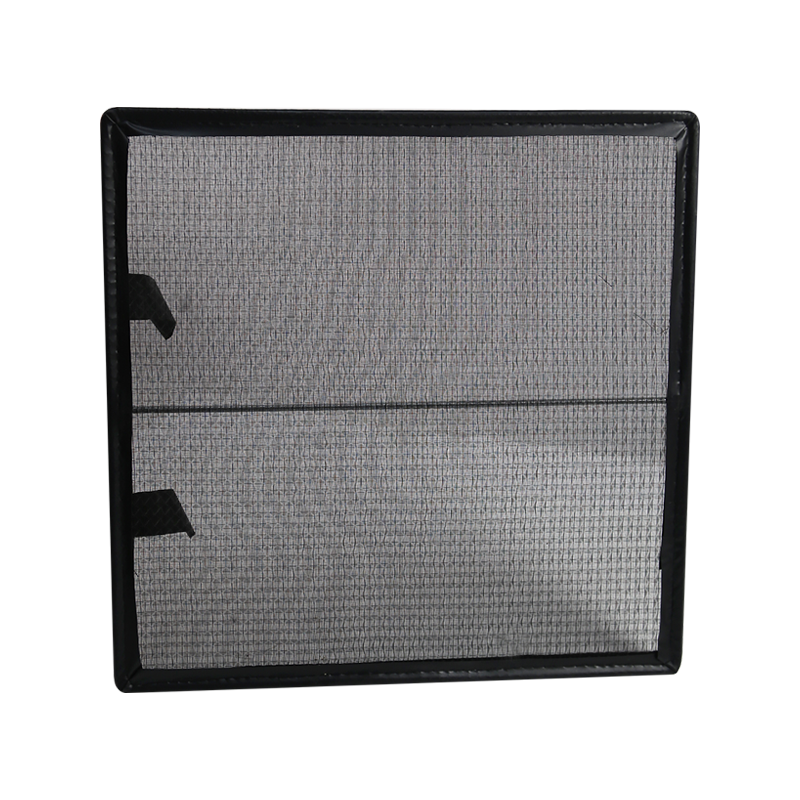

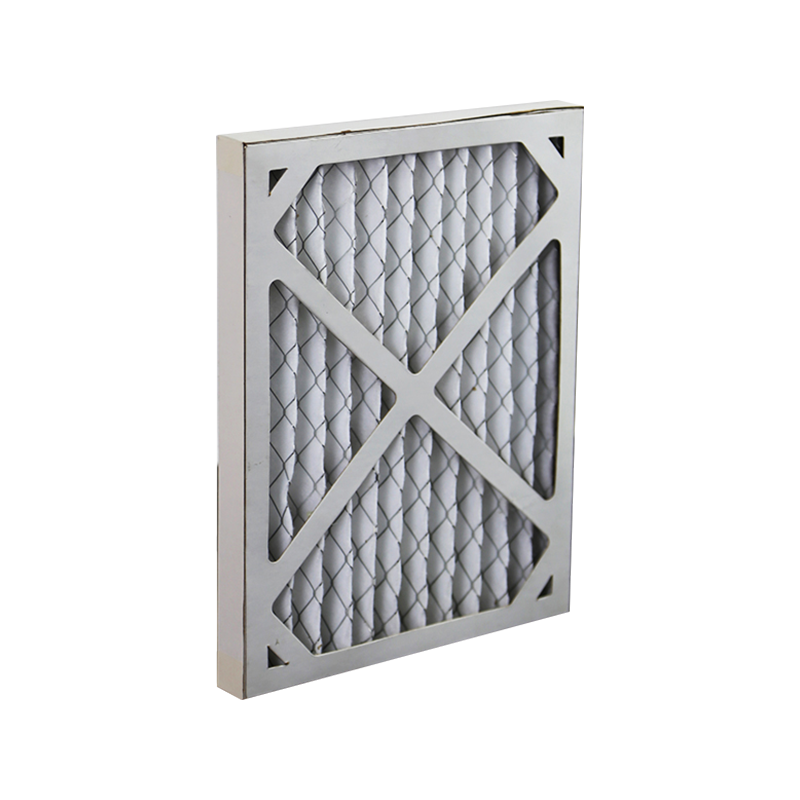

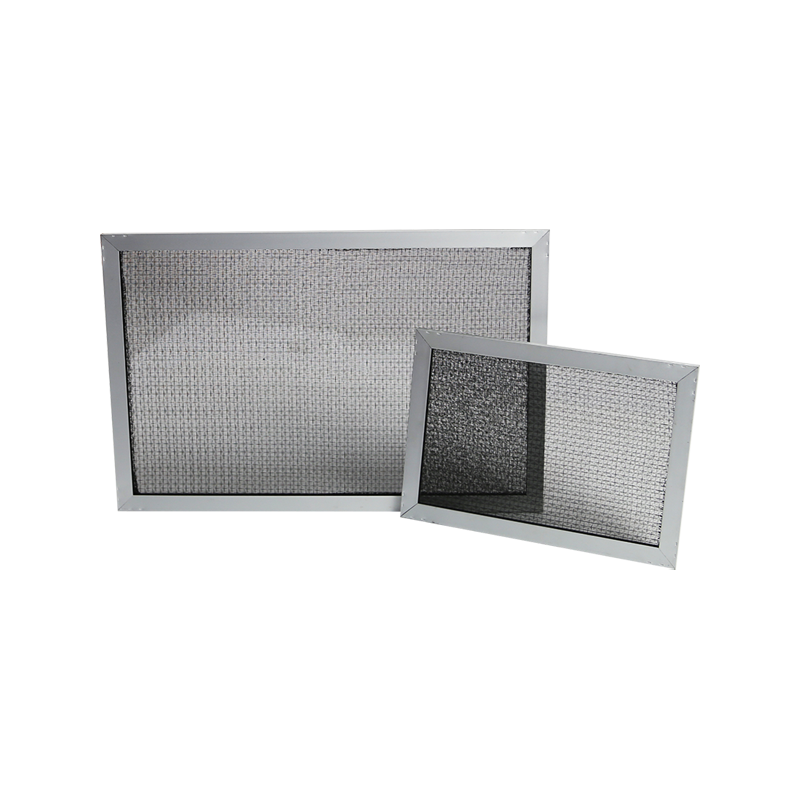

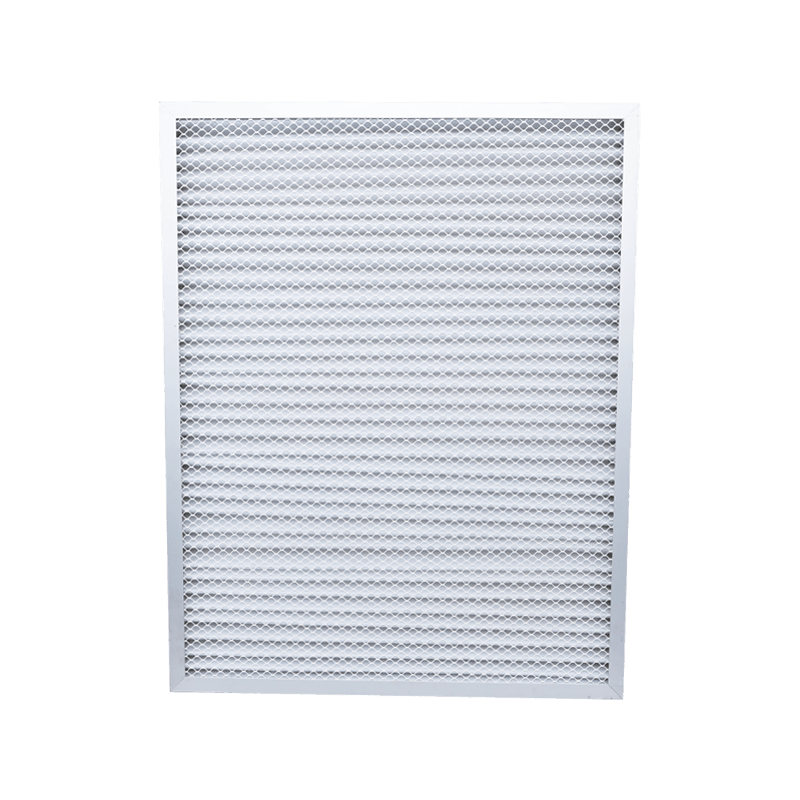

Panel filters are flat or slightly pleated air filters typically installed in frames or filter banks. They are widely used in commercial HVAC systems, office buildings, and residential applications due to their simple structure, low initial cost, and ease of replacement. Panel filters rely on surface filtration or shallow pleating to capture airborne particles.

While effective for basic air quality control, panel filters face limitations in high-dust environments, continuous operation systems, and applications requiring extended maintenance intervals. Their flat geometry restricts the amount of filter media available, which directly affects service life and pressure stability.

Higher Dust-Holding Capacity Through Cylindrical Design

One of the most significant benefits of cylindrical high efficiency air filters is their superior dust-holding capacity. The cylindrical structure allows for a much larger surface area of filter media compared to panel filters of similar installation size. More media means more space to trap contaminants before airflow resistance reaches critical levels.

In environments with heavy particulate loads such as cement plants, metal processing workshops, or woodworking facilities, this advantage translates into fewer filter changes and more consistent air quality. Panel filters, by contrast, tend to load quickly and require frequent replacement under the same conditions.

Improved Airflow and Lower Pressure Drop

Cylindrical high efficiency air filters are engineered to maintain stable airflow with lower initial and operational pressure drop. The radial airflow path distributes air evenly across the entire filter surface, reducing localized clogging and turbulence. This results in smoother airflow and less strain on fans and blowers.

Panel filters often experience uneven airflow distribution, particularly as dust accumulates. This can cause sharp increases in pressure drop, forcing ventilation systems to work harder and consume more energy. Over time, the efficiency gap between cylindrical and panel filters becomes increasingly apparent.

Energy Efficiency and Operating Cost Advantages

Lower pressure drop directly contributes to energy savings. Cylindrical high efficiency air filters help reduce fan power consumption, which is a major operating cost in large-scale air handling systems. Even small reductions in resistance can result in significant energy savings when systems run continuously.

Panel filters may appear cost-effective at purchase, but their shorter lifespan and higher energy impact often lead to higher total cost of ownership. Cylindrical filters, although sometimes higher in upfront cost, deliver better long-term economic performance through reduced energy use and fewer replacements.

Extended Service Life and Reduced Maintenance

The extended service life of cylindrical high efficiency air filters is a key reason they are preferred in industrial and mission-critical environments. Their high dust capacity and uniform loading characteristics allow them to remain effective for months or even years, depending on operating conditions.

In contrast, panel filters typically require frequent inspection and replacement, increasing maintenance labor and downtime. For facilities operating 24/7 or in remote locations, minimizing maintenance intervention is a decisive advantage.

Filtration Efficiency and Particle Capture Performance

Cylindrical high efficiency air filters are designed to achieve high filtration ratings, often meeting or exceeding HEPA or high-MERV standards depending on the media used. The depth filtration mechanism allows particles of different sizes to be captured throughout the media thickness rather than only on the surface.

Panel filters primarily rely on surface filtration, which can limit their ability to capture fine particles consistently over time. As surface pores become blocked, efficiency may fluctuate and airflow resistance rises rapidly.

Structural Strength and System Reliability

The cylindrical form provides inherent structural strength, allowing these filters to withstand higher airflow velocities and pressure differentials without deformation. Metal end caps, reinforced cores, and robust sealing systems help maintain filter integrity under demanding conditions.

Panel filters are more susceptible to warping, bypass leakage, and media collapse, especially when exposed to high airflow or moisture. This can compromise system performance and reduce filtration effectiveness.

Application Flexibility Across Industries

Cylindrical high efficiency air filters are widely used across industries including power generation, pharmaceuticals, food processing, automotive manufacturing, and cleanroom environments. Their adaptability to high airflow and strict air quality requirements makes them suitable for complex industrial systems.

Panel filters remain more common in offices, retail spaces, and residential buildings where airflow demands and contamination levels are moderate. The choice often depends on the performance expectations and operating environment.

Comparison of Cylindrical Filters and Panel Filters

| Cylindrical High Efficiency Air Filter | Panel Filter |

| Large filter media surface area | Limited surface area |

| Lower pressure drop over time | Pressure drop increases quickly |

| Long service life | Shorter replacement cycles |

| Suitable for high airflow systems | Best for low to moderate airflow |

When Cylindrical High Efficiency Air Filters Are the Better Choice

Cylindrical high efficiency air filters are particularly advantageous in systems where uptime, energy efficiency, and consistent air quality are essential. Facilities operating in dusty environments or with continuous airflow demands benefit most from their performance characteristics.

- Industrial ventilation and dust collection systems

- Gas turbines and power generation facilities

- Clean manufacturing and controlled environments

Final Practical Considerations for Filter Selection

When comparing cylindrical high efficiency air filters to panel filters, the decision should be based on total lifecycle cost rather than initial price alone. Factors such as airflow requirements, contamination levels, maintenance access, and energy consumption all influence the optimal choice.

For high-demand systems, cylindrical filters consistently deliver better performance, reliability, and long-term value. Panel filters remain useful for simpler applications, but their limitations become evident as operational demands increase.

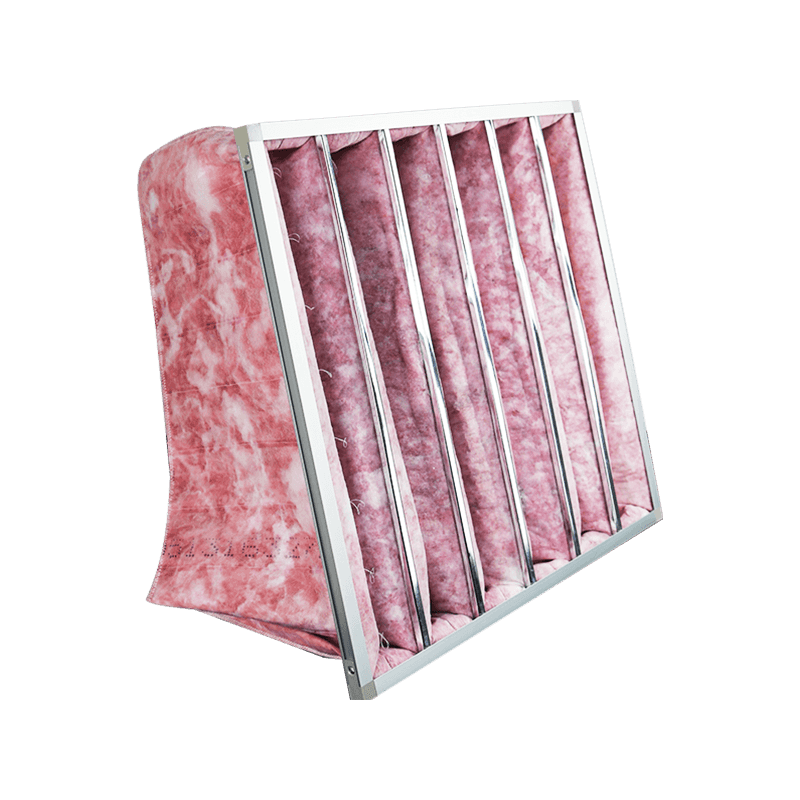

What Are Pocket Bag Air Filters and How Do You Choose the Right One?

Which Industries Commonly Use Aluminum Separator Air Filters and Why Are They Preferred?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文