From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

How Do Primary Air Filters Improve Equipment Protection and Airflow Efficiency?

Primary air filters are the first and most critical line of defense in air intake systems for engines, HVAC equipment, industrial machinery, and compressors. Their main function is to remove dust, dirt, pollen, soot, and other airborne contaminants before the air reaches sensitive internal components. By stopping harmful particles at the earliest stage, primary air filters help maintain performance, extend equipment life, and reduce overall operating costs.

In many systems, the primary air filter works together with secondary or safety filters. While secondary filters provide an additional layer of protection, the primary filter handles the bulk of contaminant loading. This makes its design, material, and maintenance schedule especially important for reliability and efficiency.

Key Functions of Primary Air Filters

Primary air filters are designed to balance two critical goals: high filtration efficiency and low airflow restriction. If a filter captures too few particles, contaminants can damage components. If it restricts airflow too much, it can reduce system performance and increase energy consumption. A well-designed primary air filter achieves an optimal balance between these factors.

- Remove large and fine particulate contaminants from intake air

- Protect engines, blowers, and internal components from abrasive wear

- Maintain consistent airflow for stable performance

- Reduce maintenance frequency and downtime

Common Types of Primary Air Filters

Primary air filters are available in several designs to suit different operating environments and equipment requirements. The choice of filter type depends on dust load, particle size, airflow rate, and service conditions.

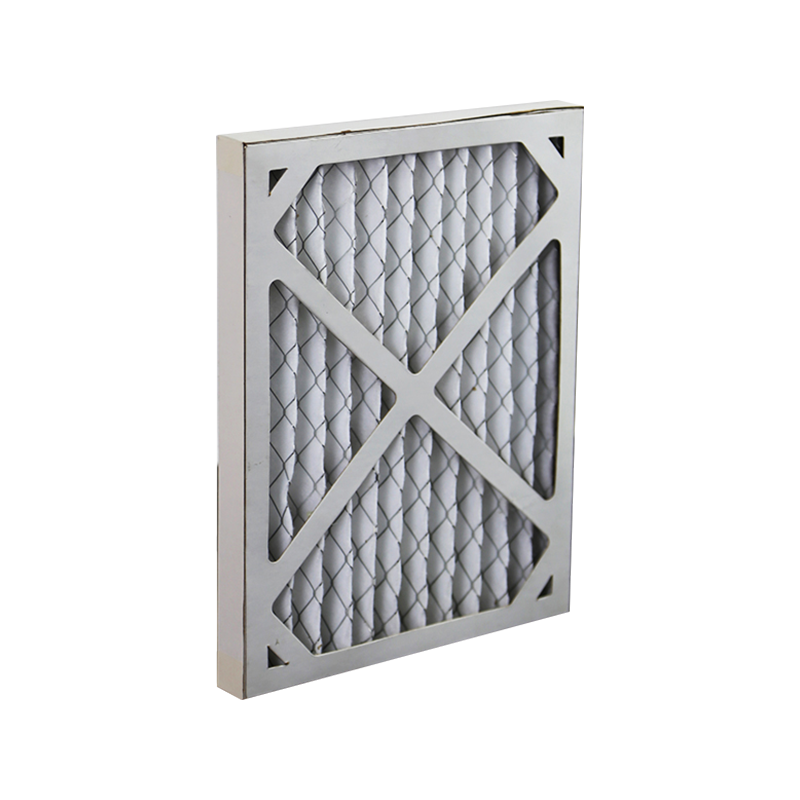

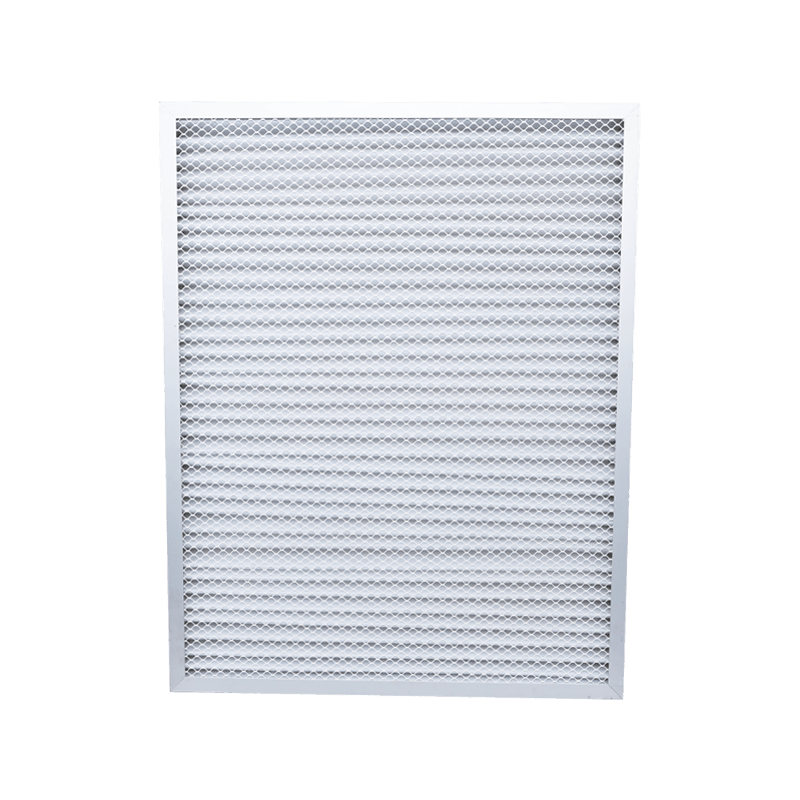

Pleated Paper Filters

Pleated paper filters are widely used in automotive, construction, and light industrial applications. The pleated structure increases surface area, allowing the filter to hold more dust while maintaining airflow. These filters are cost-effective and easy to replace, making them popular for routine maintenance.

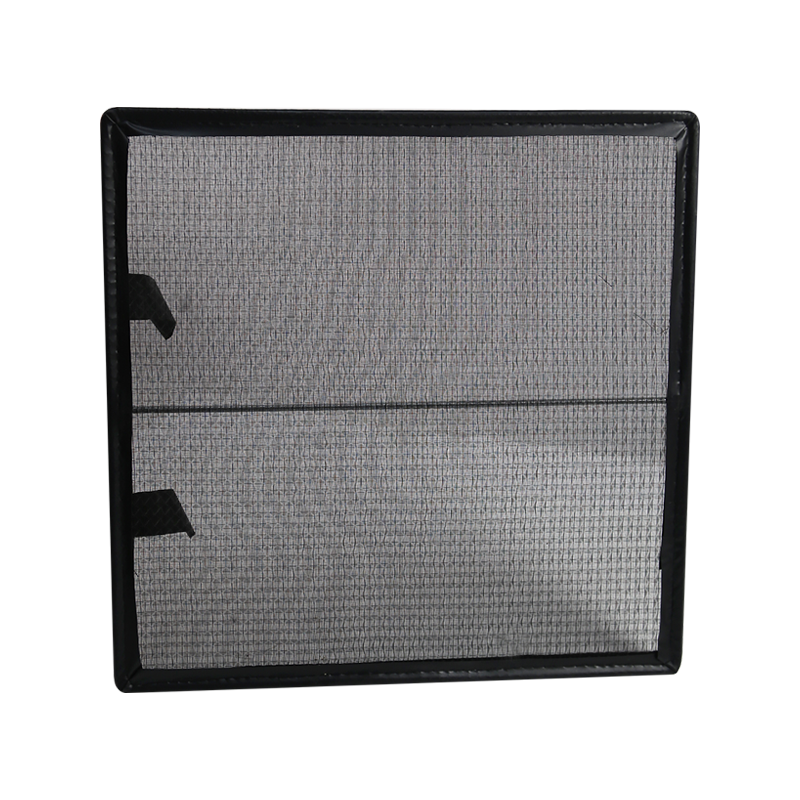

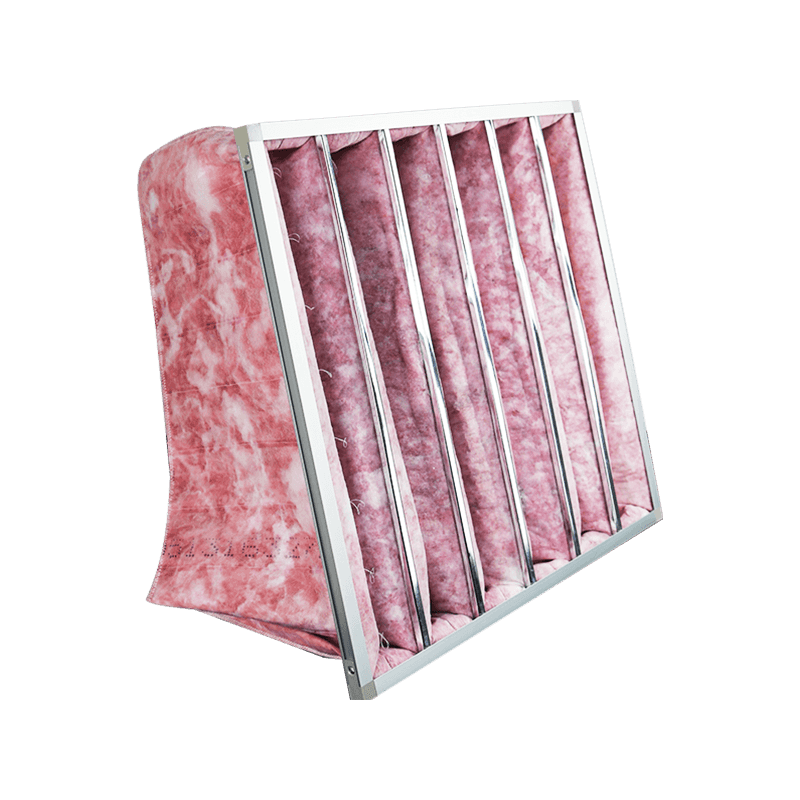

Synthetic Media Filters

Synthetic media filters use advanced fibers to improve dust-holding capacity and moisture resistance. Compared to traditional paper, synthetic filters often provide longer service life and more consistent performance in humid or dusty environments.

Foam Air Filters

Foam filters are commonly used in off-road equipment and small engines. They can be washed and reused, making them suitable for environments with heavy dust loads. However, they typically require more frequent cleaning and proper oiling to maintain filtration efficiency.

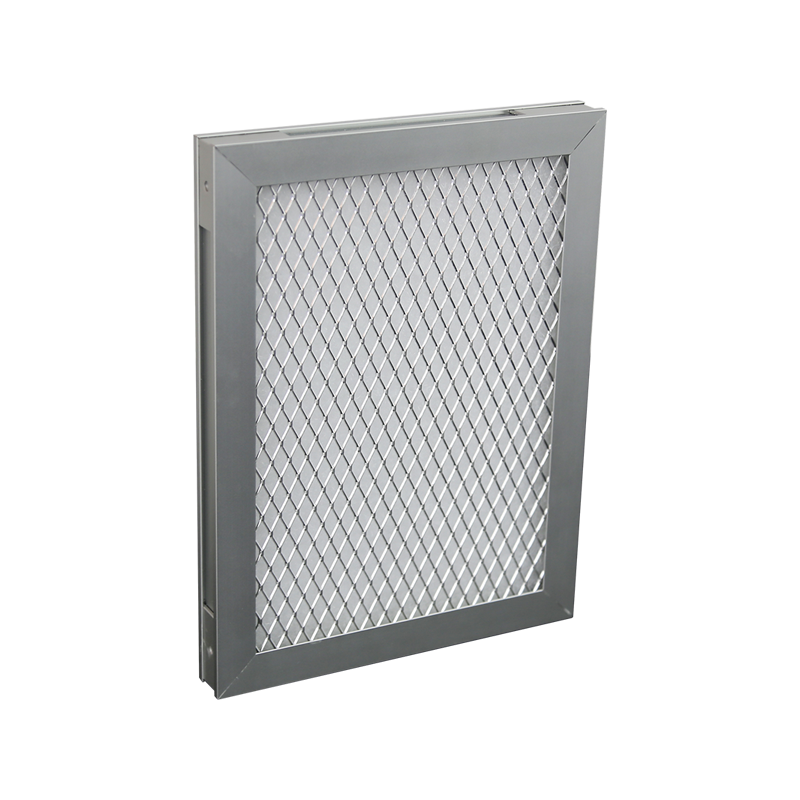

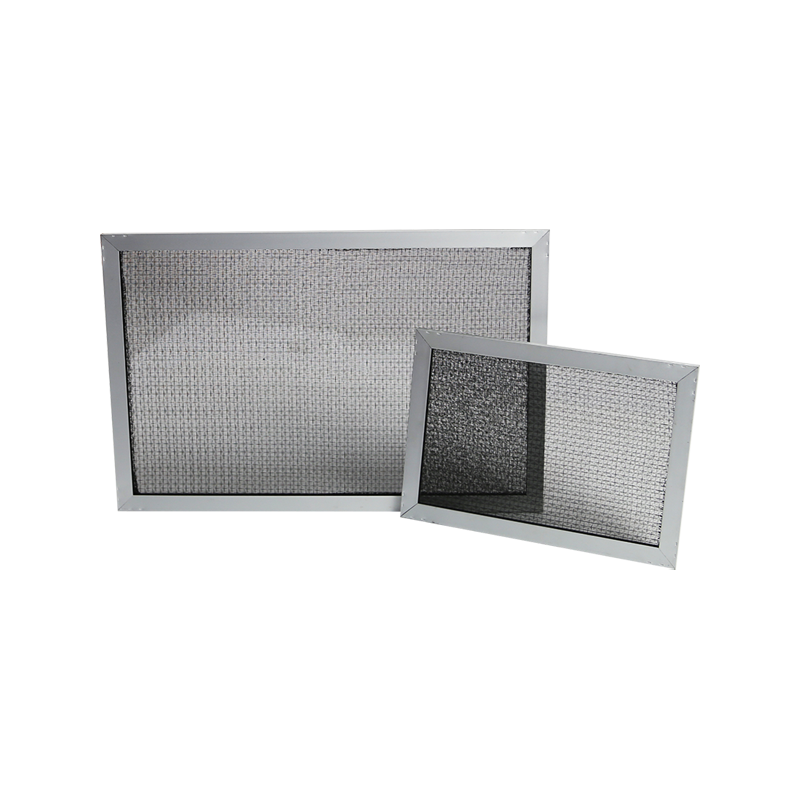

Metal Mesh and Pre-Filters

Metal mesh or coarse pre-filters are sometimes used as primary filters in extremely dusty conditions or as a first-stage filter. They capture large debris and extend the life of finer downstream filters.

Applications of Primary Air Filters

Primary air filters are used across a wide range of industries and equipment types. Each application places unique demands on the filter in terms of airflow, contaminant type, and service intervals.

- Automotive and commercial vehicles

- Construction and mining equipment

- Agricultural machinery

- Industrial compressors and blowers

- HVAC systems and air handling units

Filtration Efficiency and Particle Size

Filtration efficiency refers to the percentage of particles a filter can remove at a given particle size. Primary air filters are typically rated to capture a wide range of particle sizes, from large dust particles to fine particulates that can cause long-term wear.

In engine applications, even small amounts of fine dust can act as an abrasive, accelerating wear on pistons, cylinders, and bearings. For HVAC and industrial systems, fine particles can reduce heat transfer efficiency and contaminate downstream processes. Selecting a primary air filter with appropriate efficiency is essential for long-term system protection.

Airflow Resistance and Pressure Drop

As a primary air filter captures dust, airflow resistance increases. This is measured as pressure drop across the filter. Excessive pressure drop can reduce engine power, increase fuel or energy consumption, and strain fans or blowers.

High-quality primary air filters are designed to load dust evenly across the media, maintaining stable airflow for longer periods. Monitoring pressure drop is a best practice to determine when a filter should be serviced or replaced.

Primary vs. Secondary Air Filters

In many critical systems, a secondary or safety filter is installed downstream of the primary air filter. The primary filter handles most contaminants, while the secondary filter provides backup protection in case of leaks, improper installation, or extreme dust events.

| Filter Type | Main Role | Typical Efficiency |

| Primary Air Filter | Capture most dust and debris | Moderate to high |

| Secondary/Safety Filter | Protect against leaks or failures | Very high |

How to Choose the Right Primary Air Filter

Selecting the correct primary air filter requires understanding both the equipment requirements and the operating environment. A filter that performs well in a clean indoor setting may fail quickly in a dusty outdoor application.

- Airflow rate and system specifications

- Dust concentration and particle size distribution

- Operating temperature and humidity

- Service interval and maintenance capabilities

Installation Best Practices

Even the best primary air filter will not perform correctly if it is installed improperly. Air leaks around the seal can allow unfiltered air to bypass the filter, reducing protection and increasing contamination risk.

Always ensure that the filter housing is clean, the gasket is intact, and the filter is seated correctly. After installation, visually inspect for gaps and verify that the housing is properly secured.

Maintenance and Replacement Intervals

Primary air filters should be serviced or replaced based on condition rather than a fixed calendar schedule whenever possible. Monitoring pressure drop, visual inspection, and performance indicators provide more accurate guidance.

In harsh environments, filters may require more frequent attention. Failing to replace a heavily loaded filter can reduce system efficiency and increase long-term repair costs.

Cost Considerations and Total Cost of Ownership

While low-cost primary air filters may seem attractive, they can lead to higher total costs if they require frequent replacement or provide poor filtration. High-quality filters with better media and design often last longer and protect equipment more effectively.

Evaluating total cost of ownership includes filter price, service life, maintenance labor, energy or fuel consumption, and potential equipment wear. In many cases, investing in a higher-performance primary air filter results in measurable long-term savings.

Future Trends in Primary Air Filter Technology

Advances in filtration media, such as nanofiber layers and hybrid synthetic blends, are improving both efficiency and dust-holding capacity. These technologies allow primary air filters to capture finer particles while maintaining low pressure drop.

As equipment becomes more sensitive and emissions and efficiency standards become stricter, primary air filters will continue to play an increasingly important role in protecting systems and optimizing performance.

Conclusion: The Strategic Role of Primary Air Filters

Primary air filters are not just consumable components; they are strategic elements of system protection and performance. By selecting the right filter, installing it correctly, and maintaining it based on real operating conditions, organizations can significantly extend equipment life, reduce downtime, and control operating costs.

Understanding how primary air filters work and how to optimize their use is a practical step toward more reliable, efficient, and cost-effective operations across automotive, industrial, and HVAC applications.

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文