Quick-Release Cylindrical Air Filter

The quick-release cylindrical air filter is a device used to effectively filter particulate pollutants in the air. It adopts a cylindrical design and combines a quick-release structure, which is convenient for frequent maintenance. Its core function is to protect equipment (such as engines, air compressors, etc.) from damage caused by dust, dirt and other impurities, thereby relatively extending the service life of the equipment. Henkaes engineers suggest that the filter paper for such industrial air filters should be equipped with glass fiber or PTFE filter paper, because these two materials hardly experience efficiency decline during effective use and have relatively stable filtration performance.

Performance Parameter

| Collection Efficiency(%) |

0.3μm | 99.10% | Dust:DOP Dust Velocity:32L/Min |

| 0.5μm | 99.51% | ||

| 1.0μm | 100.00% | ||

| 2.0~5.0μm | 100.00% |

Filtration efficiency of PTFE filter paper Structure and design features of air filters

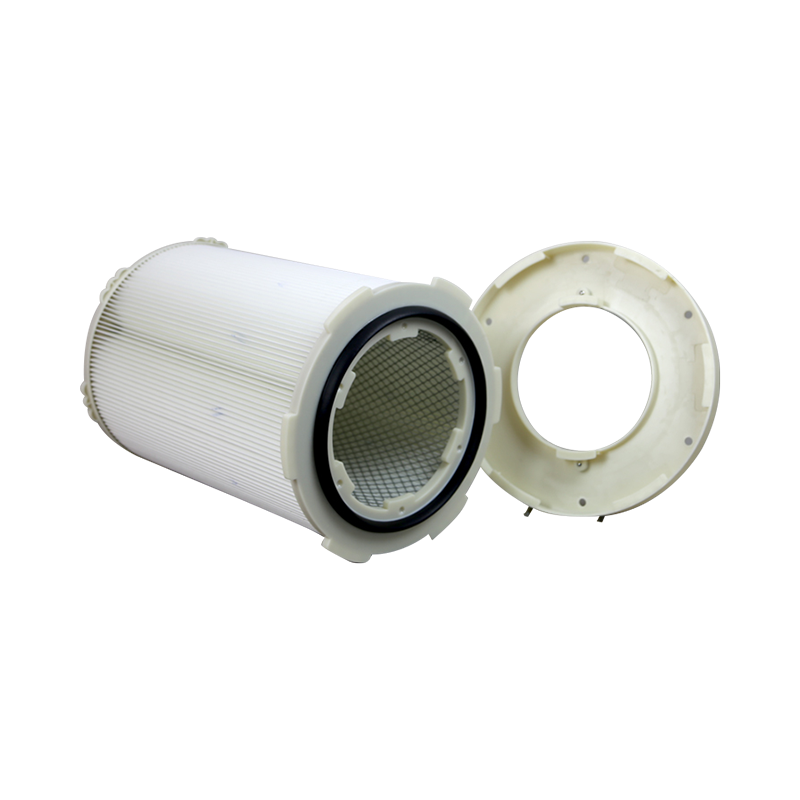

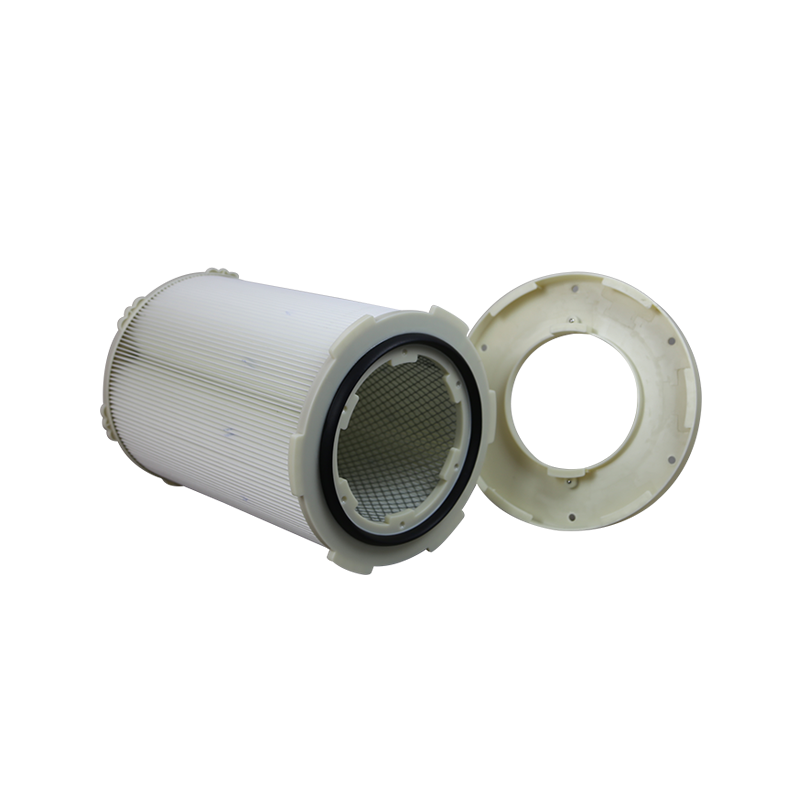

1. Quick-Release mechanism: It adopts a rotating snap, which can be disassembled without tools, making a quick replacement and saving maintenance time.

2. Pulse reverse blowing dust cleaning system: The filter element can be relatively extended in service life through dust cleaning. The multi-angle blowing method of the spray method makes the dust cleaning more effective.

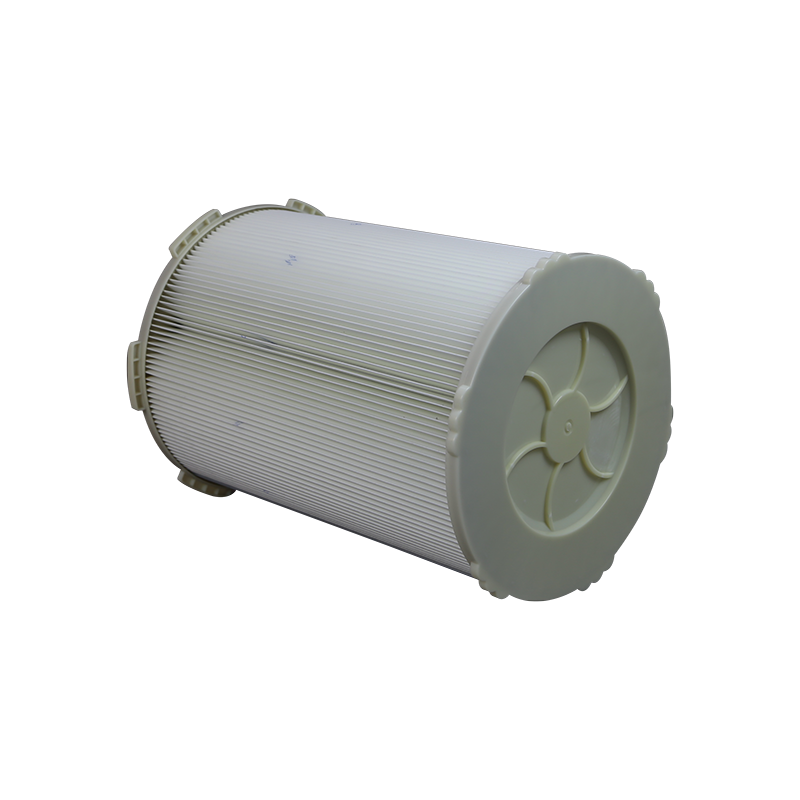

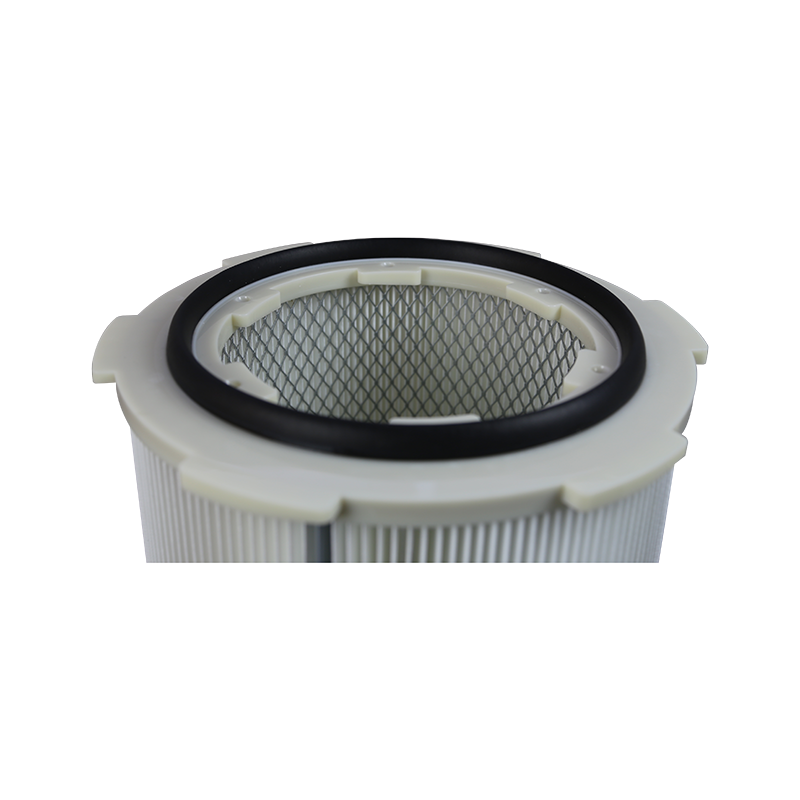

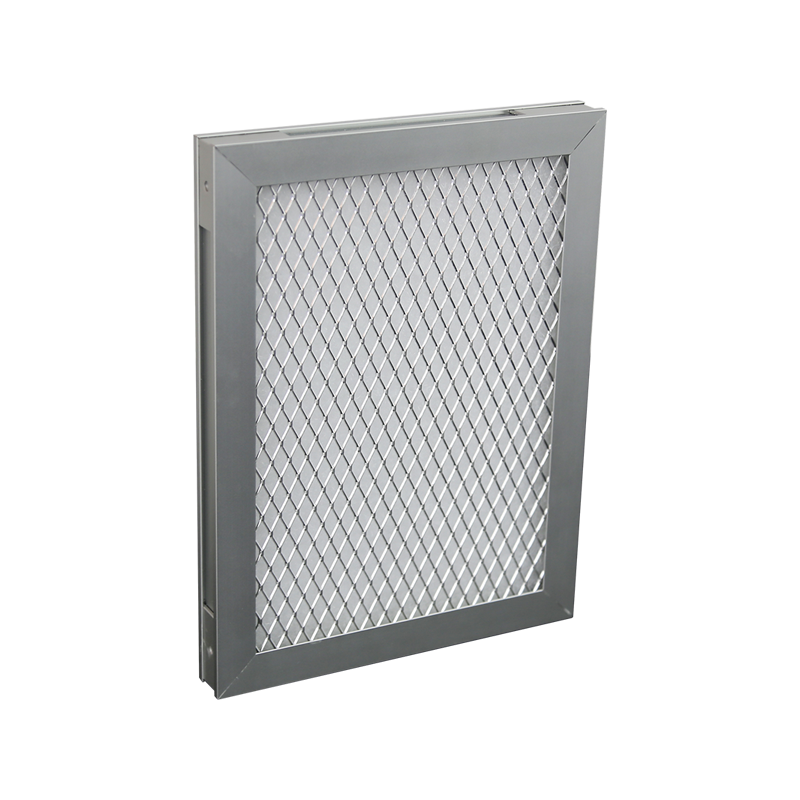

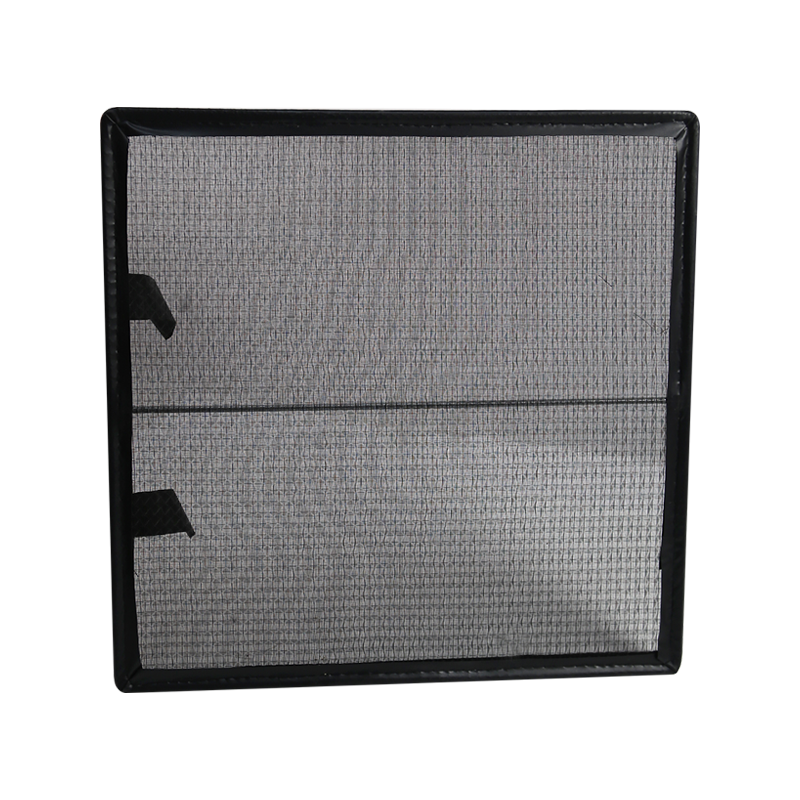

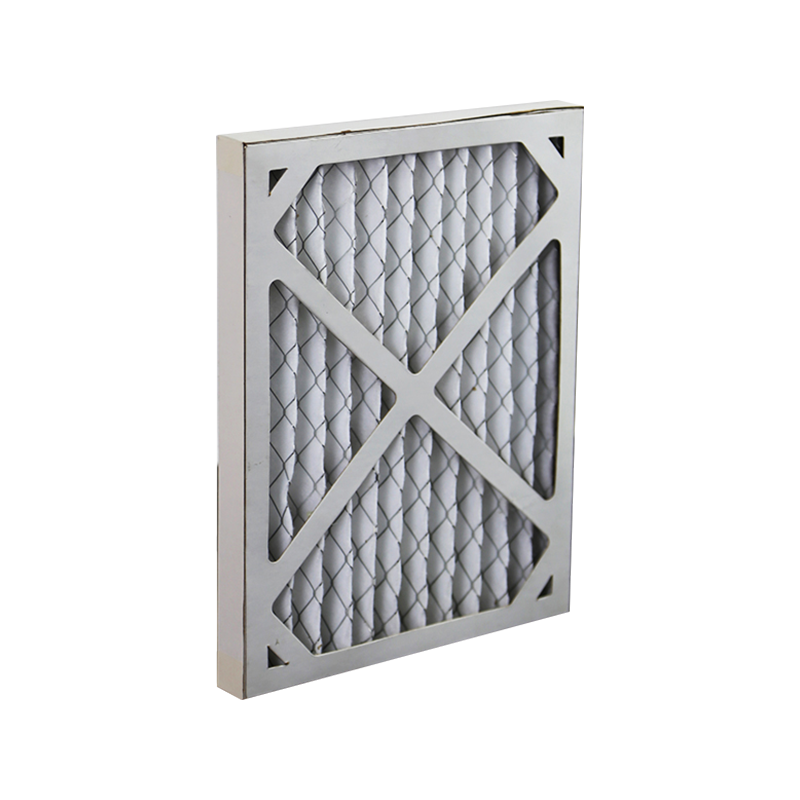

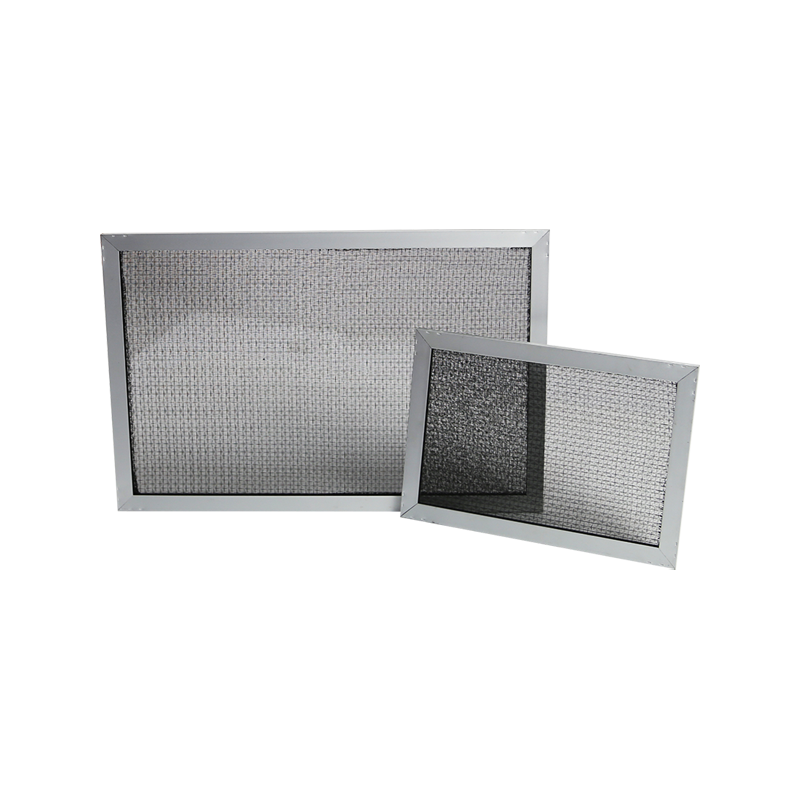

3. Filter element material: Multi-stage filtration can be designed as required. The outer layer uses a metal mesh to pre-filter large particles, and the inner layer uses PTFE filter paper to capture micron-sized particles. The PTFE material selected by Henkaes has a filtration efficiency of over 99%, a smooth surface and is easy to back-blow. Some models can withstand an environment above 120°C and are suitable for high-temperature working conditions.

4. Sealing design: The top of the air filter is sealed with a silicone or rubber ring to prevent air leakage.

This type of Quick-Release design application scenarios

1. Automotive field: Turbocharged engine intake filtration, quick-release design suitable for 4S stores for quick maintenance.

2. Industrial equipment: Inlet filtration for air compressors and gas turbines can reduce downtime for maintenance.

3. Energy industry: Gas-fired power stations filter sand and dust can meet the high-frequency replacement requirements in windy and sandy environments.

The core advantages of quick-release air filters

Replacement time: With a quick-release structure design, the replacement time can be relatively reduced to save labor costs.

Economy: By optimizing the dust holding capacity design, the replacement frequency is reduced, relatively lowering maintenance costs.

Anti-misinstallation: Asymmetrical slots are designed to prevent installation errors.

English

English русский

русский Español

Español 简体中文

简体中文