From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

What Are the Differences Between Mini Pleated HEPA Filters and Traditional HEPA Filters?

High-Efficiency Particulate Air (HEPA) filters are widely recognized for their exceptional ability to capture airborne particles, allergens, and microorganisms, making them a critical component in maintaining clean indoor air. Over the years, different HEPA filter designs have emerged to meet the needs of various applications. Two prominent types are traditional HEPA filters and mini pleated HEPA filters. While both serve the primary function of air purification, they differ in design, efficiency, application, airflow resistance, and maintenance requirements.

This article explores the differences between mini pleated HEPA filters and traditional HEPA filters, discussing their structure, performance, applications, advantages, limitations, and maintenance considerations.

1. Understanding HEPA Filters

HEPA filters are designed to trap at least 99.97% of airborne particles as small as 0.3 microns, including dust, pollen, mold spores, bacteria, and certain viruses. These filters are commonly used in:

- Residential air purifiers

- Medical and laboratory facilities

- Automotive air filtration systems

- Industrial cleanrooms

The effectiveness of a HEPA filter depends on its material, pleat design, and airflow management. Over time, innovations like mini pleated HEPA filters have been developed to address limitations in space, airflow, and filtration efficiency.

2. Structural Differences

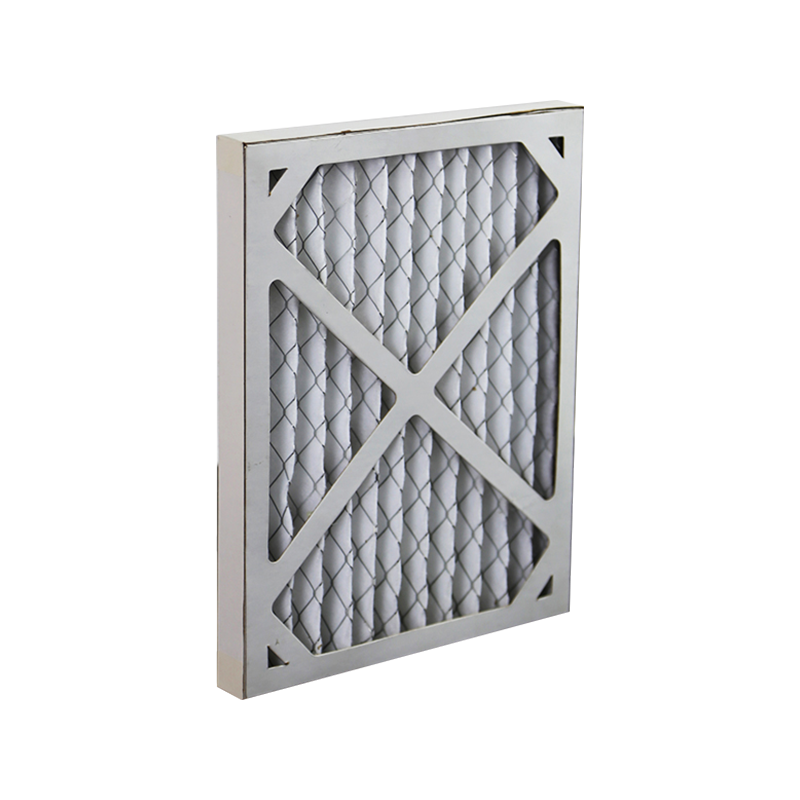

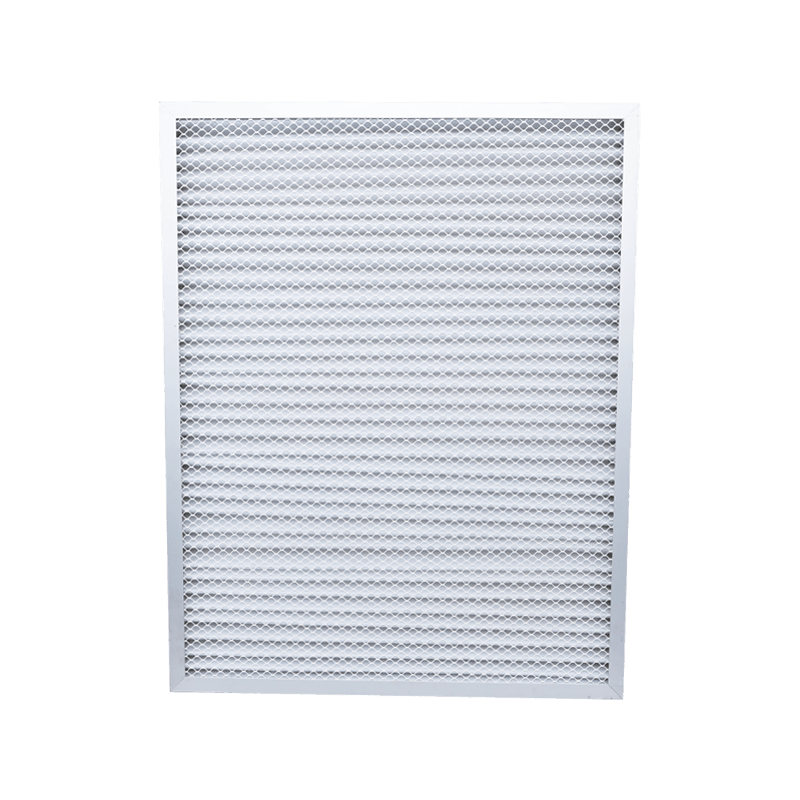

2.1 Traditional HEPA Filters

Traditional HEPA filters typically feature:

- Large, flat or slightly pleated sheets: These filters often have a depth of several inches to accommodate large volumes of air.

- Rigid frame construction: Frames are usually made from metal or plastic, providing durability and stability.

- High airflow resistance: Due to dense media and large surface area, they can create significant pressure drops in HVAC systems.

Traditional HEPA filters are often installed in residential HVAC systems, hospital air ducts, or industrial cleanrooms, where space is sufficient to accommodate their size.

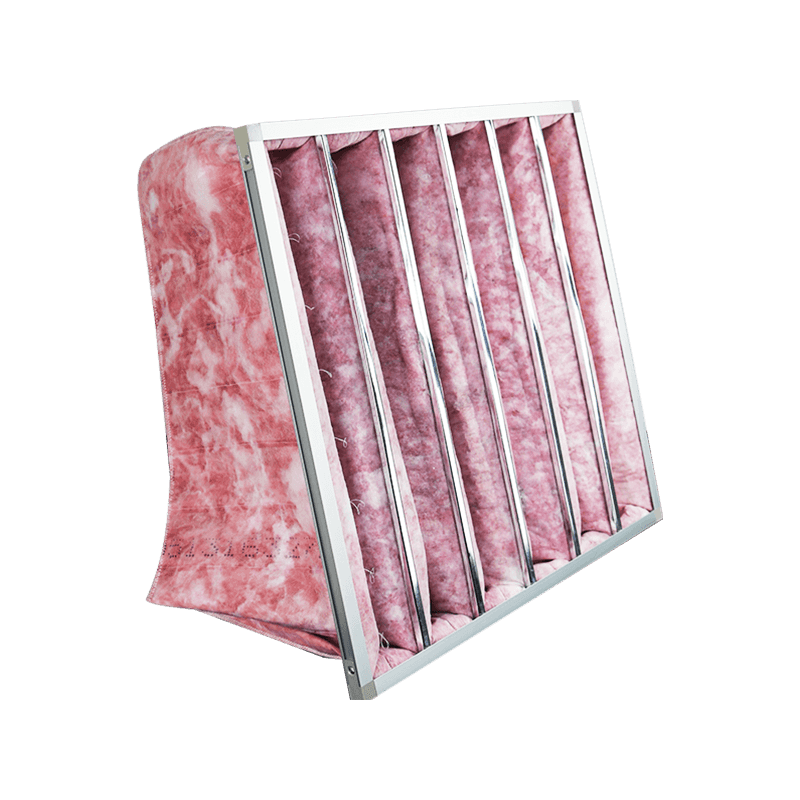

2.2 Mini Pleated HEPA Filters

Mini pleated HEPA filters differ structurally:

- Compact size: Designed to fit smaller spaces and devices such as portable air purifiers, automotive cabins, and HVAC units with limited filter compartments.

- Tightly packed pleats: The mini pleated design increases surface area while maintaining a small overall footprint.

- Flexible or modular frame: Often lightweight, allowing for easy installation and replacement in compact systems.

- Enhanced airflow efficiency: The smaller, densely packed pleats allow for effective filtration with lower resistance compared to traditional designs.

This compact form factor makes mini pleated HEPA filters ideal for applications where space and airflow management are critical.

3. Filtration Performance

3.1 Particle Capture Efficiency

- Both traditional and mini pleated HEPA filters meet the HEPA standard of 99.97% removal of 0.3-micron particles.

- Mini pleated filters often have an advantage in surface-area-to-volume ratio, allowing them to trap more particles without requiring excessive depth.

3.2 Airflow Resistance

- Traditional HEPA filters, due to their thicker media, may cause higher pressure drops, which can strain HVAC systems or fans.

- Mini pleated HEPA filters are designed to maintain high filtration efficiency with lower airflow resistance, improving energy efficiency and reducing fan load.

3.3 Lifespan and Dust-Holding Capacity

- Traditional filters can hold more dust due to their larger size but may require stronger support frames to maintain pleat integrity.

- Mini pleated filters are more compact but can still provide a substantial dust-holding capacity because of the tightly packed pleats, making them suitable for smaller systems that require frequent airflow monitoring.

4. Applications

4.1 Traditional HEPA Filters

Traditional HEPA filters are commonly used in environments where high airflow and large-scale filtration are required:

- Hospitals and clinics: Operating rooms and patient wards rely on traditional HEPA filters for infection control.

- Cleanrooms and laboratories: Critical for pharmaceutical manufacturing, electronics assembly, and biotech research.

- Residential central HVAC systems: Large systems benefit from high-volume filtration with minimal maintenance.

4.2 Mini Pleated HEPA Filters

Mini pleated HEPA filters are optimized for compact and portable applications:

- Portable air purifiers: Provide high-efficiency filtration in a small form factor for home or office use.

- Automotive cabin air filters: Fit compact HVAC compartments while ensuring passenger air quality.

- Compact HVAC units: Ideal for spaces with limited filter housing, such as small apartments or modular systems.

- Medical devices: Used in CPAP machines, ventilators, and other medical equipment requiring compact, high-efficiency filtration.

5. Advantages and Limitations

5.1 Advantages of Traditional HEPA Filters

- Large surface area allows for high dust-holding capacity.

- Durable frames and thick media withstand industrial and heavy-duty applications.

- Suitable for high-volume airflow systems, maintaining filtration over larger areas.

Limitations:

- Bulky and less suitable for compact systems.

- Higher airflow resistance may require more powerful fans.

- Installation and replacement can be more cumbersome due to size.

5.2 Advantages of Mini Pleated HEPA Filters

- Compact size allows use in portable or confined applications.

- High surface-area efficiency ensures excellent filtration with lower airflow resistance.

- Easier to replace, handle, and transport due to lightweight construction.

- Energy-efficient design reduces fan load and operating costs.

Limitations:

- Smaller size may reduce total dust-holding capacity compared to larger traditional filters.

- More frequent replacement may be required in high-dust environments.

- Not suitable for large-scale industrial air handling without multiple units.

6. Maintenance Considerations

Proper maintenance is crucial for both filter types to maintain efficiency:

6.1 Traditional HEPA Filters

- Periodic inspection: Check for dirt accumulation and physical damage.

- Replacement schedule: Often ranges from 6–12 months, depending on usage and environment.

- Cleaning: Most traditional HEPA filters are non-washable; replacing the filter is recommended.

6.2 Mini Pleated HEPA Filters

- Compact design allows easy replacement: Typically every 3–6 months, depending on usage.

- Visual monitoring: Transparent or semi-transparent housings may allow users to see dust buildup.

- Cleaning limitations: Most mini pleated filters are also non-washable, but their smaller size makes disposal and replacement convenient.

7. Cost and Availability

- Traditional HEPA filters are generally more expensive due to larger material usage and durable frames. Bulk purchases for HVAC or industrial systems may reduce per-unit cost.

- Mini pleated HEPA filters are more cost-effective for portable devices or automotive applications but may require more frequent replacement, balancing cost over time.

- Both types are widely available from OEMs and aftermarket suppliers, with compatibility determined by system requirements.

8. Future Trends

The demand for high-efficiency filtration continues to grow due to increasing concerns about indoor air quality, allergens, and airborne pathogens. Trends include:

- Nano-fiber technology: Enhances filtration efficiency while maintaining low airflow resistance.

- Antimicrobial coatings: Reduce bacterial and mold growth on filter surfaces.

- Eco-friendly materials: Recyclable or biodegradable media for sustainability.

- Smart filters: Sensors integrated into mini pleated HEPA filters to monitor airflow, usage, and replacement needs.

Both traditional and mini pleated HEPA filters are evolving to meet stricter performance standards while addressing energy efficiency and environmental concerns.

9. Conclusion

While traditional HEPA filters and mini pleated HEPA filters share the same primary purpose of removing airborne particles and contaminants, they differ significantly in design, size, airflow management, and application:

- Traditional HEPA filters: Ideal for large-scale, high-volume systems requiring high dust-holding capacity and durable construction.

- Mini pleated HEPA filters: Optimized for compact, portable, and energy-efficient systems where space and airflow resistance are critical.

Choosing between the two depends on the specific application, airflow requirements, available space, and maintenance considerations. Both filter types play a vital role in improving indoor air quality, protecting sensitive environments, and ensuring the health and comfort of occupants.

By understanding these differences, consumers, manufacturers, and facility managers can make informed decisions about the most suitable HEPA filtration solution for their needs.

What Are the Key Advantages of Activated Carbon Air Filters Compared to HEPA Filters?

How Do Medium Efficiency Bag Filters Compare to High-Efficiency Filters in Terms of Performance?

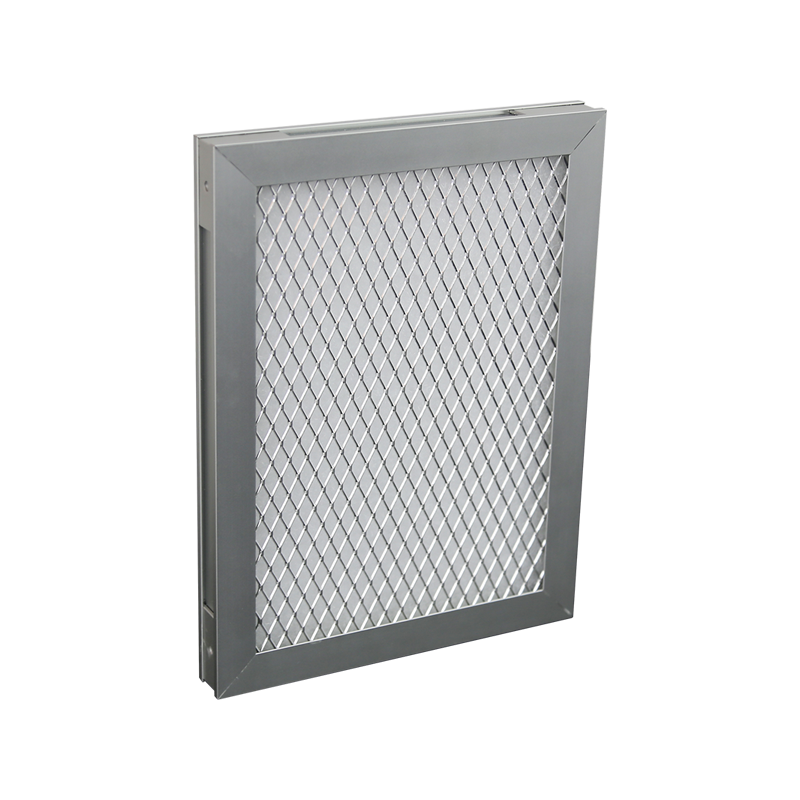

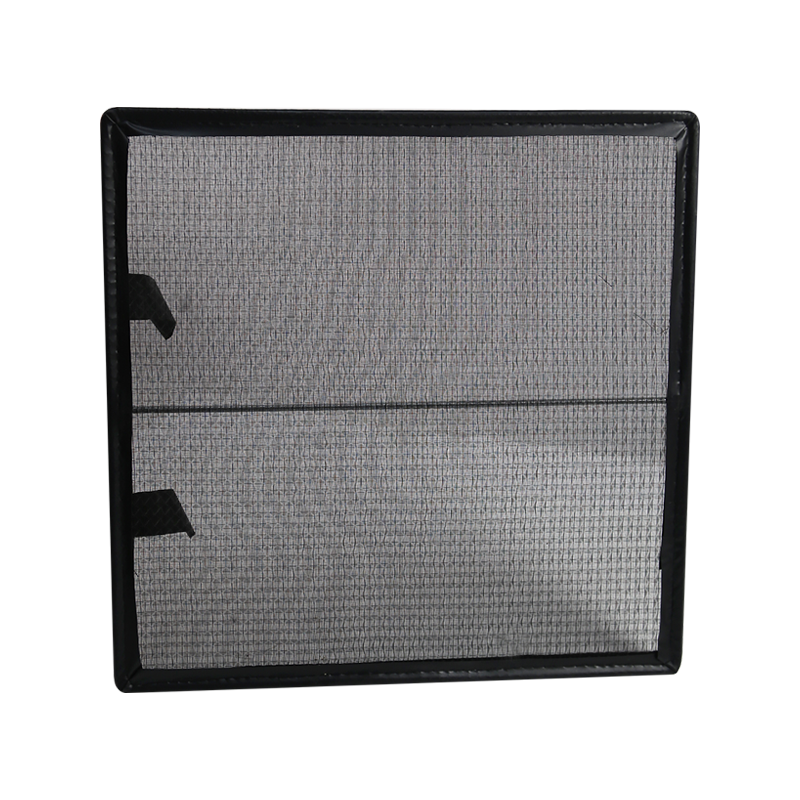

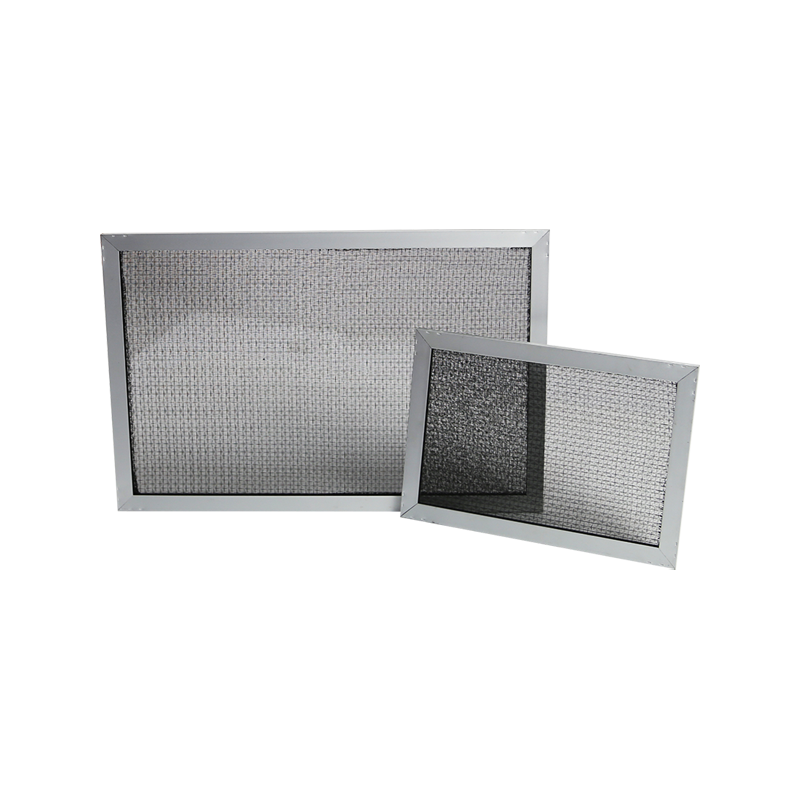

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文