From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

How Do Medium Efficiency Bag Filters Compare to High-Efficiency Filters in Terms of Performance?

When it comes to filtration systems—whether for HVAC systems, industrial air quality management, or water filtration—the choice between medium efficiency bag filters and high-efficiency filters is critical. Both types of filters play essential roles in improving air quality, enhancing operational performance, and maintaining the health of both equipment and the environment. However, they differ significantly in terms of performance, cost, and suitability for specific applications.

In this article, we will explore how medium efficiency bag filters compare to high-efficiency filters in terms of performance, and which type of filter might be the best choice for various applications.

1. Understanding Medium Efficiency Bag Filters

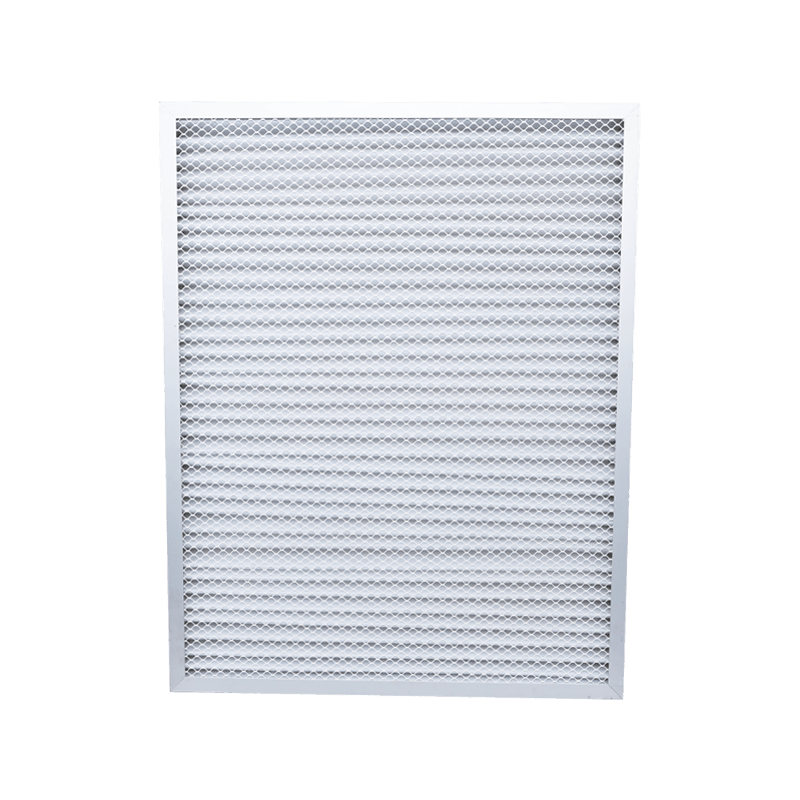

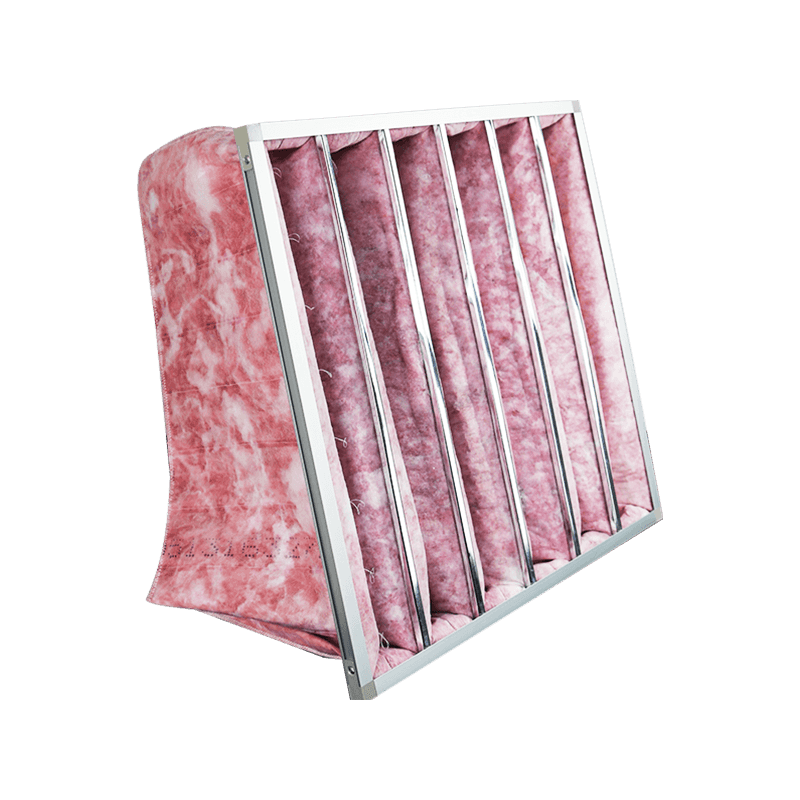

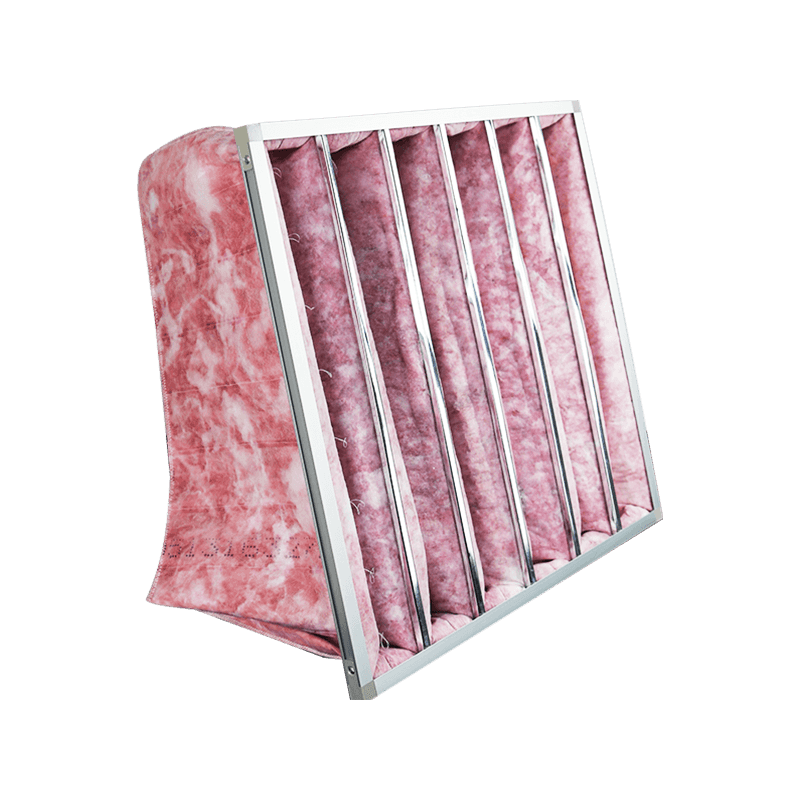

Medium efficiency bag filters are designed to capture a range of particles of varying sizes. Typically, they are rated to capture particles in the 1 to 10 micrometer range, which includes a variety of airborne contaminants such as dust, pollen, mold spores, and other larger particulate matter. These filters are commonly used in environments where there is a moderate level of air contamination or in areas where a balance of filtration and airflow is needed.

Medium efficiency filters are commonly used in HVAC systems, industrial ventilation, and in commercial buildings where energy efficiency and air quality are equally important. They are also a cost-effective option for systems that require decent filtration without necessarily needing to capture very fine particles like bacteria or viruses.

Key Features of Medium Efficiency Bag Filters:

- Filtration Efficiency: Medium efficiency filters typically offer 40% to 85% efficiency, depending on the specific class and manufacturer. This means they capture a significant portion of larger particles but may not be sufficient for environments that require the filtration of ultra-fine particulates.

- Airflow Resistance: Medium efficiency bag filters provide a balance between filtration performance and low airflow resistance, which means they won’t overly restrict airflow, making them ideal for general commercial and industrial use.

- Durability: These filters are generally designed to handle moderate contaminant levels and have a decent lifespan before needing replacement or cleaning.

2. What Are High-Efficiency Filters?

High-efficiency filters are designed to capture finer particles at a much higher rate than medium efficiency filters. These include filters like HEPA (High-Efficiency Particulate Air) filters, which are capable of capturing up to 99.97% of particles as small as 0.3 microns. This makes high-efficiency filters ideal for applications where maintaining a very high level of air purity is crucial, such as in clean rooms, pharmaceutical environments, hospitals, or laboratories.

High-efficiency filters are typically more expensive due to the specialized materials used and the tighter construction that enables them to capture finer particles. Their main role is to prevent the passage of pollutants that can cause serious health concerns or contamination in highly sensitive environments.

Key Features of High-Efficiency Filters:

- Filtration Efficiency: High-efficiency filters are designed to capture up to 99.97% of particles, especially those as small as 0.3 microns, which include dust, allergens, bacteria, and even some viruses. They are often used in environments where the control of airborne particles is essential.

- Airflow Resistance: High-efficiency filters typically have higher airflow resistance compared to medium efficiency filters. This can lead to a more significant drop in airflow in HVAC systems and industrial systems if not properly accounted for in system design.

- Durability and Maintenance: Due to their dense filtering media, high-efficiency filters tend to need more frequent maintenance or replacement. The buildup of fine particles can clog the filter faster, making it necessary to replace them more often.

3. Performance Comparison: Medium Efficiency vs. High-Efficiency Filters

Now, let’s compare medium efficiency bag filters and high-efficiency filters across several key performance areas:

3.1 Filtration Efficiency

The primary difference between medium efficiency and high-efficiency filters is their filtration efficiency. High-efficiency filters excel at trapping very small particles, often down to 0.3 microns. This makes them ideal for environments requiring stringent air quality standards, such as hospitals, clean rooms, or pharmaceutical facilities. High-efficiency filters, particularly HEPA filters, are highly effective in filtering out dust, bacteria, pollen, and even viruses.

In contrast, medium efficiency bag filters capture larger particles, typically in the 1 to 10 micron range. They are sufficient for general air filtration in commercial buildings, offices, and factories where air purity is important but not critical.

- High-Efficiency Filters: Typically 99.97% efficient for 0.3-micron particles.

- Medium Efficiency Filters: Generally 40% to 85% efficient, depending on the class.

Conclusion: High-efficiency filters are far superior when it comes to filtering out smaller, more dangerous particles, while medium-efficiency filters are more suited for environments where high filtration is not as critical.

3.2 Airflow Resistance

One of the drawbacks of high-efficiency filters is their higher airflow resistance. Because these filters are made with denser materials designed to trap very fine particles, they tend to cause a significant reduction in airflow. In HVAC systems, this can lead to increased energy consumption as fans have to work harder to push air through the filter.

Medium efficiency bag filters, on the other hand, are designed with a balance between filtration and airflow. They generally allow for greater airflow with lower resistance, which makes them more energy-efficient in systems that don’t require highly stringent filtration.

- High-Efficiency Filters: Increased airflow resistance, requiring more powerful fans or increased system energy costs.

- Medium Efficiency Filters: Lower airflow resistance, leading to better energy efficiency in many applications.

Conclusion: If energy efficiency is a priority in a less demanding application, medium efficiency bag filters may be the better option as they offer a balance between filtration and airflow.

3.3 Cost and Maintenance

High-efficiency filters are generally more expensive due to the complex materials used and the higher degree of filtration they provide. Additionally, high-efficiency filters require more frequent maintenance, especially in environments with higher levels of contaminants. This adds to their operational cost, as they will need to be replaced more often to maintain optimal performance.

Medium-efficiency filters are relatively more cost-effective. They are less expensive to purchase and maintain, and they can be cleaned and reused in many cases, making them an excellent choice for businesses looking for affordable, moderate filtration.

- High-Efficiency Filters: Higher initial cost and frequent maintenance.

- Medium Efficiency Filters: Lower initial cost, longer intervals between maintenance.

Conclusion: Medium efficiency filters are more cost-effective, both in terms of initial investment and long-term maintenance, while high-efficiency filters offer superior filtration but at a higher cost.

3.4 Suitability for Specific Applications

- High-Efficiency Filters: These are best suited for environments where air quality is of paramount importance. This includes hospitals, clean rooms, food processing facilities, and other places where airborne contaminants can affect health, safety, or the integrity of the products being produced.

- Medium Efficiency Filters: Ideal for applications where moderate air quality is sufficient, such as office buildings, commercial facilities, and industrial settings that don’t require the highest levels of filtration.

Conclusion: High-efficiency filters are best for sensitive, high-risk environments, while medium-efficiency filters are suitable for general commercial and industrial use.

4. Conclusion

In conclusion, medium efficiency bag filters and high-efficiency filters serve distinct purposes depending on the requirements of the application. Medium efficiency filters offer cost-effectiveness, low airflow resistance, and are suitable for general air filtration needs. They provide a good balance between filtration and airflow and are perfect for everyday commercial and industrial settings.

On the other hand, high-efficiency filters deliver superior filtration performance, capturing very fine particles and making them ideal for highly sensitive environments like hospitals, laboratories, and clean rooms. However, they come with higher costs, greater airflow resistance, and frequent maintenance requirements.

Ultimately, the decision to choose between medium efficiency and high-efficiency filters depends on the specific needs of the application, the acceptable level of air purity, and the cost-efficiency considerations of the system.

What Are the Differences Between Mini Pleated HEPA Filters and Traditional HEPA Filters?

What Are the Differences Between Panel Air Filters and Pleated Air Filters?

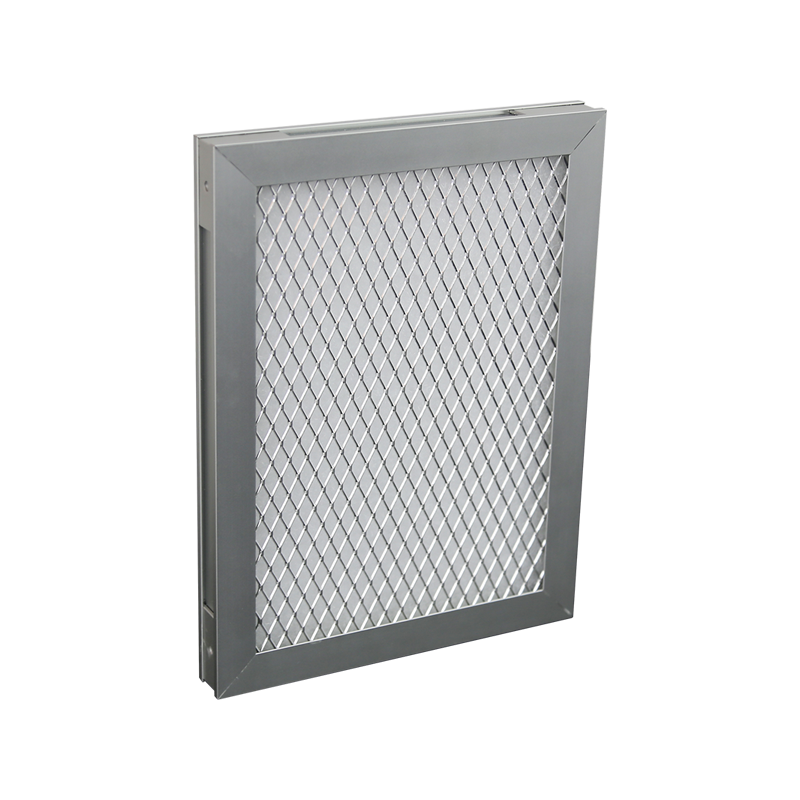

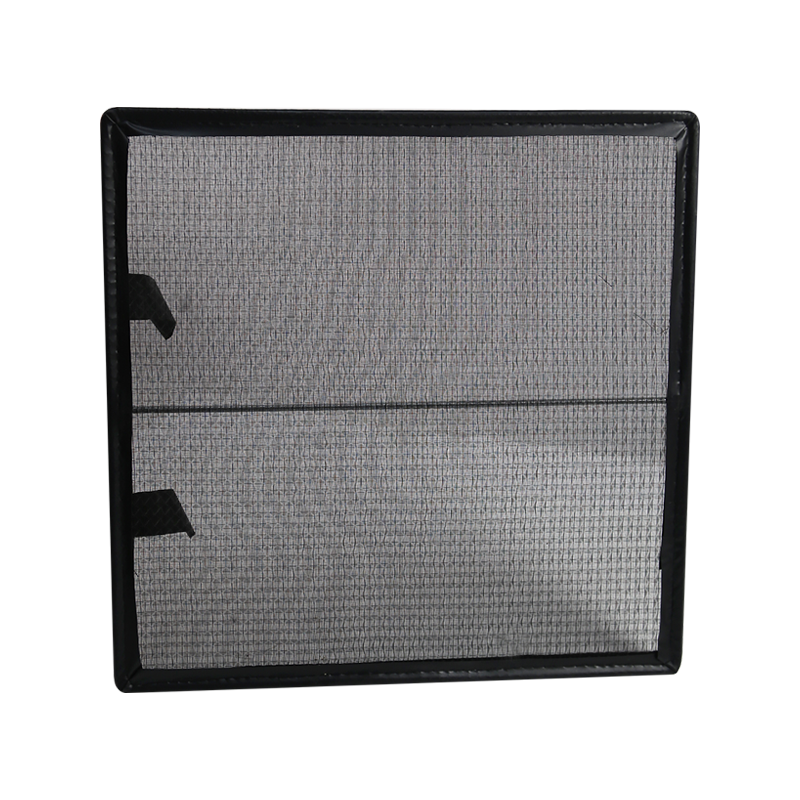

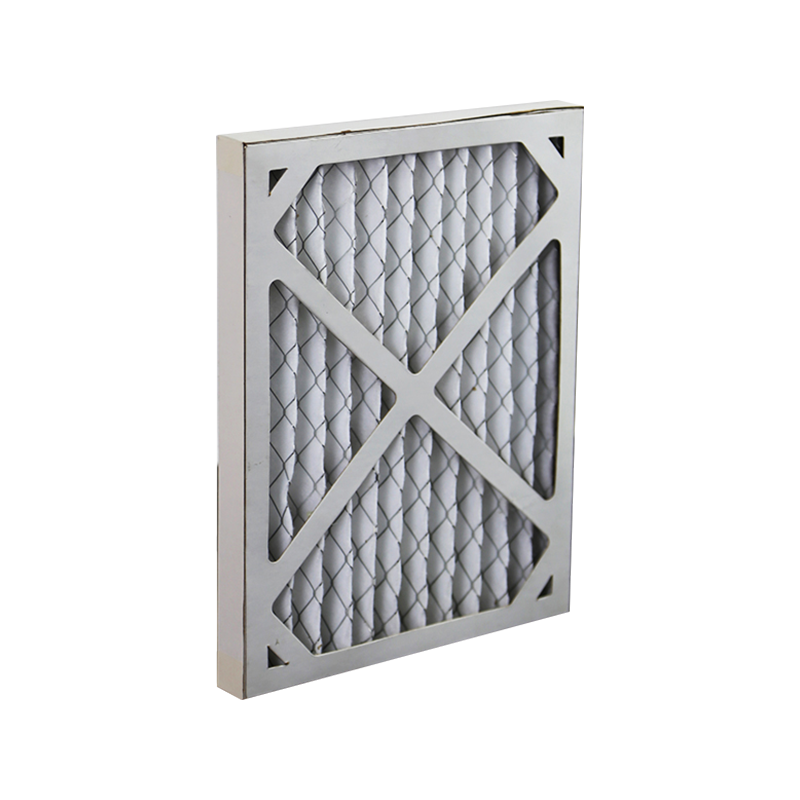

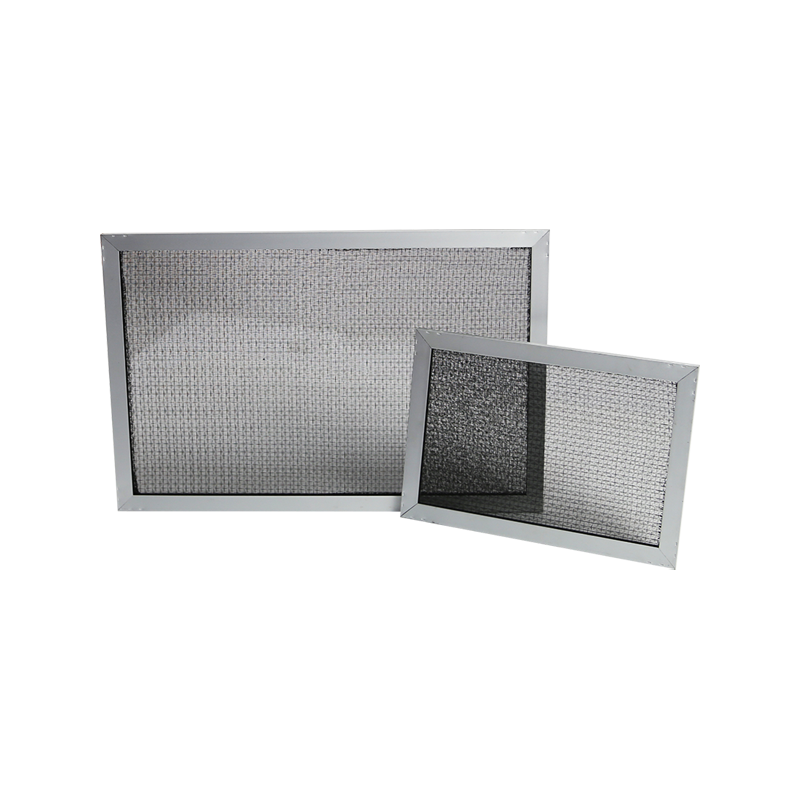

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文