From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

Mini Pleated HEPA Air Filters: Complete Selection & Usage Guide

Understanding Mini Pleated HEPA Filter Construction and Design

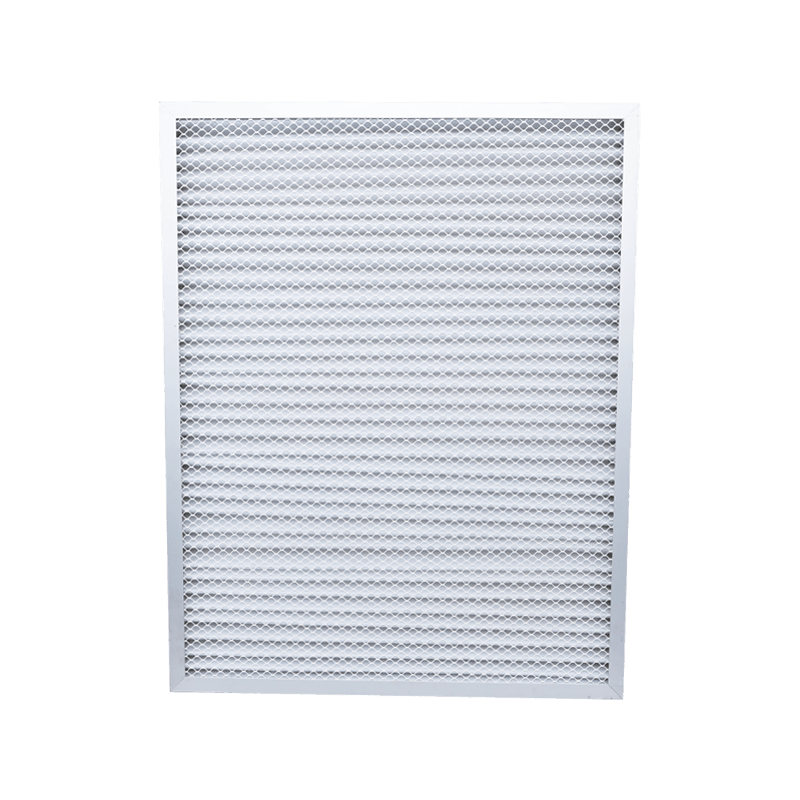

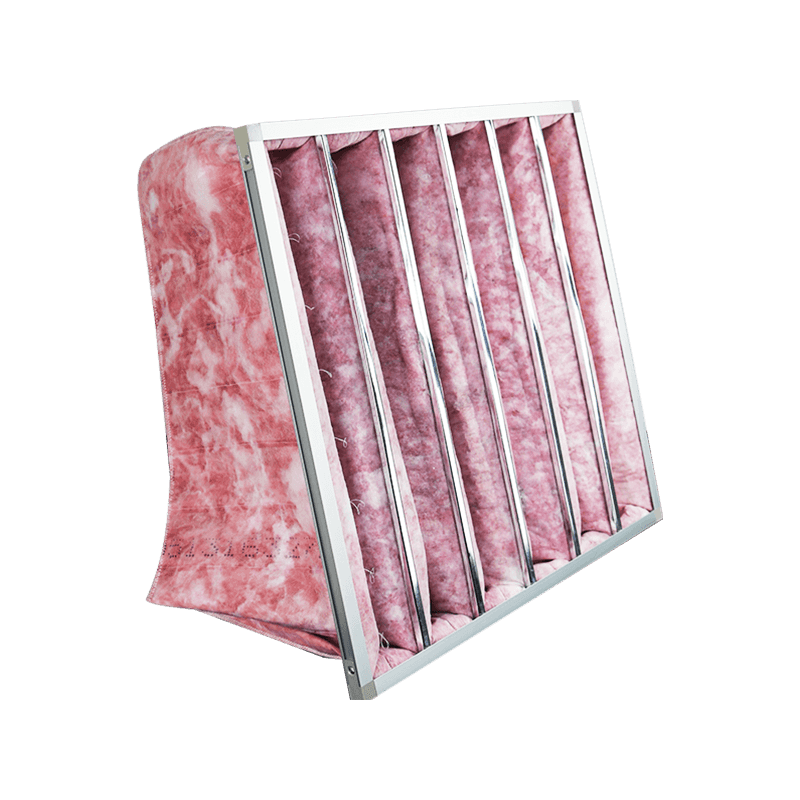

Mini pleated HEPA air filters represent a sophisticated evolution in air filtration technology, combining the exceptional particle capture efficiency of High Efficiency Particulate Air (HEPA) standards with space-saving pleated designs optimized for compact applications. These filters utilize pleated media construction that dramatically increases the effective filtration surface area within a relatively small frame size, creating more opportunities for airborne particles to contact and adhere to filter fibers. The pleating process folds the HEPA media into accordion-like configurations, with pleat counts ranging from twelve to thirty pleats per foot depending on media thickness and application requirements, maximizing filtration capacity while maintaining manageable pressure drop across the filter.

The filter media itself consists of randomly arranged microscopic fibers, typically composed of fiberglass, synthetic polymers, or blended materials engineered to achieve HEPA-grade efficiency. True HEPA filters must capture at least 99.97% of particles measuring 0.3 microns in diameter, the Most Penetrating Particle Size (MPPS) where filtration mechanisms prove least effective. The media captures particles through multiple mechanisms including inertial impaction for larger particles, interception for medium-sized particles, and diffusion for the smallest particles, with electrostatic attraction providing additional capture in some designs. Mini pleated configurations maintain these capture mechanisms while reducing overall filter dimensions, making HEPA-grade filtration practical for applications where space constraints previously precluded such high-efficiency solutions.

HEPA Classification Standards and Efficiency Ratings

Understanding the various HEPA classifications and related efficiency standards helps ensure selection of filters meeting specific application requirements, as terminology variations and marketing claims sometimes obscure actual performance characteristics.

True HEPA Versus HEPA-Type Filters

True HEPA filters meet stringent standards defined by the U.S. Department of Energy, capturing 99.97% of 0.3-micron particles in standardized testing protocols. This classification represents verified performance rather than marketing terminology, with filters undergoing rigorous testing to confirm compliance. HEPA-type or HEPA-like filters employ similar construction but fail to achieve true HEPA efficiency standards, typically capturing 85-95% of particles at 0.3 microns. While these lower-efficiency filters cost less and create reduced airflow resistance, they provide significantly diminished protection against fine particulates including allergens, bacteria, and combustion particles that pose the greatest health concerns.

International Classification Systems

European standards classify high-efficiency filters using the ISO 29463 system, with H13 and H14 grades corresponding roughly to HEPA performance levels. H13 filters capture 99.95% of particles, while H14 achieves 99.995% efficiency, both tested at MPPS. ULPA (Ultra-Low Penetration Air) filters represent even higher efficiency grades capturing 99.999% or more of particles, though these extreme performance levels rarely justify their significantly higher cost and airflow restriction in typical applications. When sourcing mini pleated filters internationally or comparing specifications across regions, verify that efficiency claims reference equivalent testing standards and particle sizes to ensure meaningful comparisons.

Common Applications for Mini Pleated HEPA Filters

The compact dimensions and high efficiency of mini pleated HEPA filters enable their use across diverse applications where space limitations or specific performance requirements demand small-footprint filtration solutions delivering exceptional particle removal.

| Application Category | Typical Uses | Key Requirements |

| Medical Equipment | Ventilators, anesthesia machines, respiratory devices | Sterilization compatibility, low resistance |

| Electronics Cooling | Server cabinets, control panels, sensitive instruments | Dust prevention, compact sizing |

| Portable Air Purifiers | Personal air cleaners, small room units | High efficiency, quiet operation |

| Laboratory Equipment | Biosafety cabinets, fume hoods, cleanroom applications | Contamination control, verified performance |

| Automotive Systems | Cabin air filtration, engine intake protection | Vibration resistance, temperature tolerance |

Sizing and Airflow Considerations

Proper filter sizing requires balancing filtration efficiency, airflow requirements, pressure drop limitations, and physical dimensional constraints to achieve optimal system performance without compromising air delivery or energy efficiency.

Calculating Required Filter Area

Filter face velocity, measured in feet per minute (FPM) or meters per second, significantly impacts both filtration efficiency and pressure drop across the media. Mini pleated HEPA filters typically operate optimally at face velocities between 250-500 FPM, with lower velocities improving efficiency and extending filter life while higher velocities reduce required filter area but increase resistance and energy consumption. Calculate minimum filter face area by dividing required airflow (CFM) by maximum acceptable face velocity, then select the next larger standard filter size providing adequate area. Systems with limited fan capacity or strict energy efficiency requirements benefit from oversized filters operating at reduced face velocities, minimizing pressure drop and fan power requirements.

Pressure Drop and System Compatibility

Mini pleated HEPA filters create initial pressure drops ranging from 0.5 to 1.5 inches of water column (w.c.) when clean, depending on media thickness, pleat depth, and airflow rate. As filters load with captured particles, pressure drop increases progressively until reaching the recommended replacement point, typically when pressure doubles from initial readings or reaches 2.0-2.5 inches w.c. Verify that system fans or blowers provide sufficient static pressure capacity to overcome filter resistance throughout the loading cycle while maintaining required airflow. Underpowered systems may deliver adequate initial performance but experience declining airflow as filters load, compromising air quality and potentially creating negative pressure issues.

Frame Materials and Seal Configurations

The frame and sealing system surrounding the pleated media proves equally important to filtration performance as the media itself, as bypass leakage around improperly sealed filters negates the benefits of high-efficiency media by allowing unfiltered air to circumvent the filtration path.

- Plastic frames offer lightweight construction, corrosion resistance, and cost-effectiveness suitable for standard applications without extreme temperature or chemical exposure

- Aluminum or stainless steel frames provide superior durability, dimensional stability, and compatibility with high-temperature or harsh chemical environments

- Moisture-resistant separator materials like aluminum or synthetic polymers prevent degradation in humid conditions where cardboard separators would fail

- Gasket seal designs using closed-cell foam, silicone, or neoprene create compression seals preventing bypass when properly installed in compatible housings

- Gel-seal configurations employ polyurethane or silicone gel bonds between media and frame, creating permanent seals ideal for critical applications requiring absolute leak prevention

- Knife-edge seals using thin flexible gaskets accommodate dimensional variations in filter housings while maintaining effective sealing under compression

Installation Best Practices for Maximum Performance

Correct installation procedures ensure mini pleated HEPA filters achieve their rated efficiency and service life while preventing common problems including bypass leakage, premature loading, or physical damage during handling and mounting.

Inspect filters upon receipt for shipping damage including crushed pleats, torn media, or frame deformation that could compromise performance. Store filters in original packaging in clean, dry environments away from temperature extremes, chemicals, or high humidity that might degrade media or adhesives before installation. Handle filters by their frames only, avoiding contact with the pleated media that could introduce oils from skin contact or cause mechanical damage to the delicate fiber structure.

Verify that filter housings are clean and free from debris, with gasket surfaces smooth and undamaged to ensure proper sealing. Install filters with airflow arrows oriented correctly, as reversed installation may damage media or create turbulent flow reducing efficiency. Apply uniform compression to gasket seals using proper mounting hardware torqued to manufacturer specifications, avoiding over-compression that could distort frames or under-compression allowing bypass leakage. Some applications require leak testing after installation using methods like aerosol photometry or pressure decay testing to verify seal integrity and overall system performance.

Maintenance Schedules and Replacement Indicators

Unlike lower-efficiency filters that may tolerate cleaning and reuse, HEPA filters represent disposable components requiring replacement rather than maintenance, with proper change-out timing crucial for sustained performance and system efficiency.

Determining Optimal Replacement Timing

Monitor pressure drop across filters using magnehelic gauges or differential pressure sensors, establishing baseline readings when filters are new and tracking increases during service. Replace filters when pressure drop reaches manufacturer-specified limits, typically when doubling from initial readings or exceeding 2.0-2.5 inches w.c., as continued operation beyond these points wastes energy through increased fan power while risking filter damage from excessive stress. Calendar-based replacement schedules provide backup timing for installations lacking pressure monitoring, with intervals ranging from three months in high-particulate environments to two years in exceptionally clean applications, though actual requirements vary significantly based on specific conditions.

Disposal and Environmental Considerations

Used HEPA filters contain accumulated particulates potentially including hazardous materials, allergens, or biological contaminants depending on application, requiring appropriate disposal procedures. Medical and laboratory applications may mandate biohazard disposal protocols or incineration to ensure pathogen destruction. Industrial applications capturing toxic dusts or carcinogenic particles necessitate hazardous waste handling according to local regulations. Standard residential and commercial applications typically allow disposal as general waste, though some facilities implement recycling programs recovering frame materials while properly disposing of contaminated media.

Performance Testing and Verification Methods

Ensuring mini pleated HEPA filters deliver specified performance requires testing both during manufacturing and after installation, with various methods available depending on required certainty and application criticality.

Factory testing typically employs standardized protocols including the DOP (Dioctyl Phthalate) smoke test or more modern PAO (Polyalphaolefin) aerosol testing, challenging filters with precisely sized particles while measuring upstream and downstream concentrations to calculate efficiency. Individual filter scanning using automated equipment maps efficiency across the entire filter face, identifying localized defects or weak spots that might escape detection in whole-filter testing. Quality manufacturers provide test certificates documenting individual filter performance, offering traceability and verification of specification compliance.

Field testing after installation verifies that the complete system, including filters, housing, and seals, achieves required performance in actual operating conditions. Aerosol photometry introduces test aerosols upstream while measuring downstream concentrations using optical particle counters, calculating system efficiency and identifying leak locations. Pressure decay testing pressurizes the system slightly while monitoring pressure loss rates, with excessive decay indicating seal leakage or housing defects. Critical applications in healthcare, pharmaceutical manufacturing, or microelectronics fabrication may require periodic retesting throughout filter service life, ensuring continued compliance with stringent air quality standards.

Cost Analysis and Economic Considerations

While mini pleated HEPA filters command premium pricing compared to lower-efficiency alternatives, comprehensive cost analysis considering energy consumption, replacement frequency, and protected equipment value often justifies the investment through total cost of ownership advantages.

Initial filter costs range from twenty dollars for small residential units to several hundred dollars for larger commercial or specialized medical-grade filters, with pricing influenced by media area, frame materials, seal type, and certification requirements. Calculate annual filter costs by dividing filter price by expected service life in years, recognizing that harsh environments with heavy particulate loading require more frequent replacement than clean applications. Factor energy costs associated with fan power overcoming filter resistance, as high-efficiency pleated designs may actually reduce energy consumption compared to less efficient flat-panel filters requiring higher airflow rates to achieve comparable air cleaning.

Consider the value of protected equipment, processes, or health outcomes when evaluating filter investments. Electronics manufacturing protecting million-dollar production equipment easily justifies premium filtration preventing contamination-related failures. Healthcare applications protecting vulnerable patients from airborne pathogens warrant highest-quality filters despite higher costs. Even residential applications may justify HEPA-grade filtration for occupants with severe allergies or respiratory conditions, where health improvements outweigh modest additional filter expenses.

Specialized Variants and Enhanced Features

Advanced mini pleated HEPA filters incorporate additional features or treatments addressing specific challenges or enhancing performance beyond standard particulate capture capabilities.

- Antimicrobial treatments using silver ions or other biocidal agents prevent bacterial and fungal growth on captured organic materials, important in humid environments or medical applications

- Activated carbon integration adds VOC and odor removal capability in combination filters addressing both particulate and gaseous contaminants

- Fire-resistant media formulations meeting UL 900 Class 1 or Class 2 standards provide safety in applications with potential ignition sources

- High-temperature variants using glass fiber media and metal components withstand continuous operation above 200°F unsuitable for standard filters

- Electrostatically charged media enhances submicron particle capture through electrostatic attraction supplementing mechanical filtration mechanisms

- Moisture-resistant constructions using synthetic media and waterproof adhesives withstand humid or wet environments where standard filters degrade

Troubleshooting Common Performance Issues

Even properly specified and installed mini pleated HEPA filters occasionally experience problems affecting performance, with systematic diagnosis and correction restoring optimal operation and preventing recurrence.

Rapid pressure increase suggests excessive particulate loading from unexpectedly high contamination levels or inadequate pre-filtration protecting the HEPA filter. Install upstream pre-filters capturing larger particles before they reach the HEPA media, extending service life and reducing replacement costs. Verify that pressure readings reflect actual conditions rather than gauge failures or blocked sensing lines providing false readings. Unusually low pressure drop may indicate bypass leakage around seals or through media tears, requiring leak testing to locate and address problem areas.

Reduced airflow without corresponding pressure increase suggests fan problems, duct restrictions, or control system issues rather than filter-related causes. Verify fan operation and check for closed dampers, collapsed ductwork, or clogged diffusers restricting flow downstream from filters. Excessive noise may result from turbulent airflow through damaged pleats, vibration of improperly secured filters, or whistling through bypass gaps, each requiring specific corrective actions. Visible media damage indicates improper handling, excessive pressure, or manufacturing defects necessitating immediate replacement to restore specified efficiency and prevent catastrophic failure releasing accumulated contaminants.

Future Developments in Compact HEPA Technology

Ongoing research and development efforts continue advancing mini pleated HEPA filter technology, pursuing improvements in efficiency, capacity, energy efficiency, and sustainability addressing evolving application requirements and environmental concerns.

Nanofiber media incorporates electrospun fibers measuring hundreds of nanometers in diameter, significantly smaller than conventional microfibers, creating extraordinarily fine pore structures capturing particles more efficiently while reducing airflow resistance. These advanced materials enable thinner filter media achieving HEPA efficiency with reduced pressure drop, or exceeding HEPA standards approaching ULPA performance without proportional resistance increases. Manufacturing cost reductions and scaling challenges currently limit widespread nanofiber adoption, though increasing availability promises future performance improvements in compact filter designs.

Sustainable materials and manufacturing processes address environmental concerns associated with disposable filters, exploring biodegradable media materials, recyclable frame components, and reduced-waste production methods. Smart filters incorporating embedded sensors monitor pressure drop, remaining service life, and even particle capture efficiency in real-time, enabling predictive maintenance and optimized replacement timing. Integration with building management systems and IoT platforms provides centralized monitoring across multiple filter locations, streamlining maintenance operations and ensuring consistent air quality throughout facilities. These innovations promise to enhance the already impressive capabilities of mini pleated HEPA filters while addressing economic and environmental challenges associated with high-efficiency air filtration.

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文