From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

How Do You Properly Maintain and Clean Aluminum Separator Air Filters?

Aluminum separator air filters are widely used in industrial, automotive, and HVAC systems to ensure clean air flow and protect machinery, engines, and indoor environments from harmful particulates. These filters are designed for durability, high airflow efficiency, and long service life. However, to maintain their performance, it is essential to implement proper maintenance and cleaning practices. Neglecting routine care can lead to reduced filtration efficiency, higher energy consumption, and premature wear of equipment.

This article provides a comprehensive guide on how to properly maintain and clean aluminum separator air filters, including practical methods, safety considerations, and tips for extending filter lifespan.

1. Understanding Aluminum Separator Air Filters

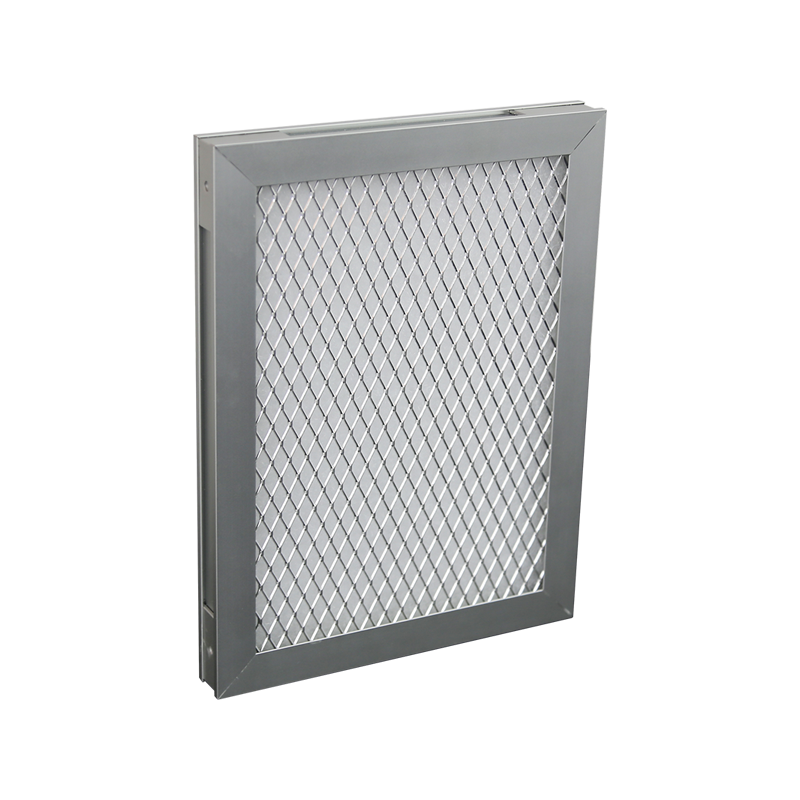

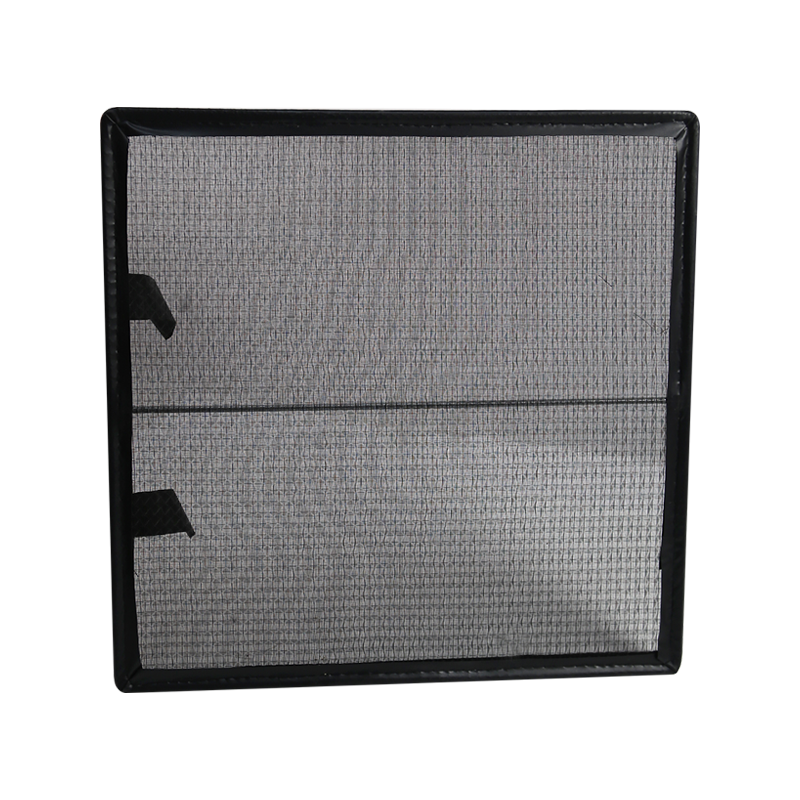

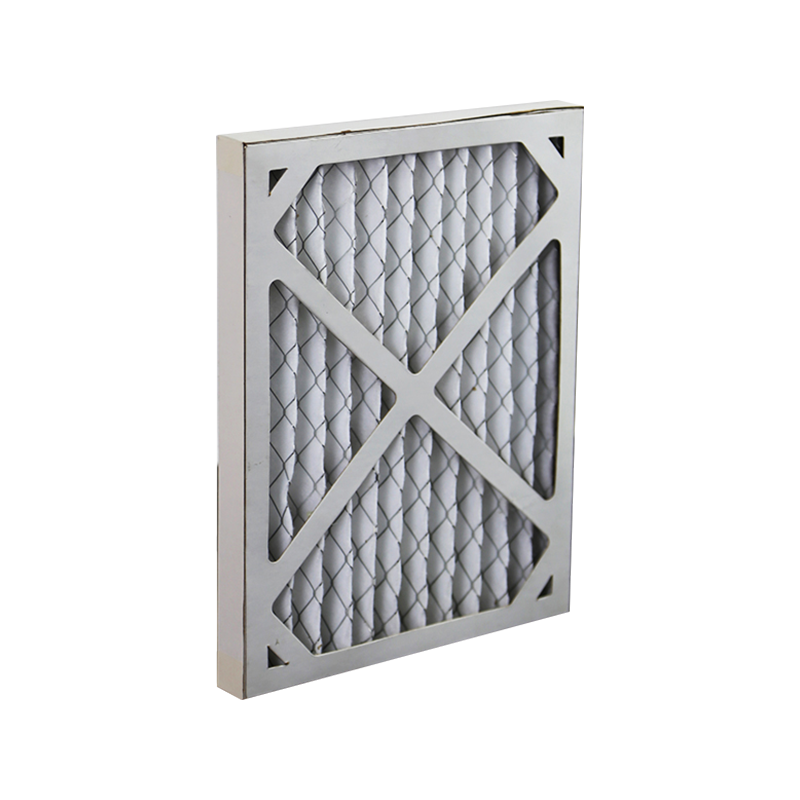

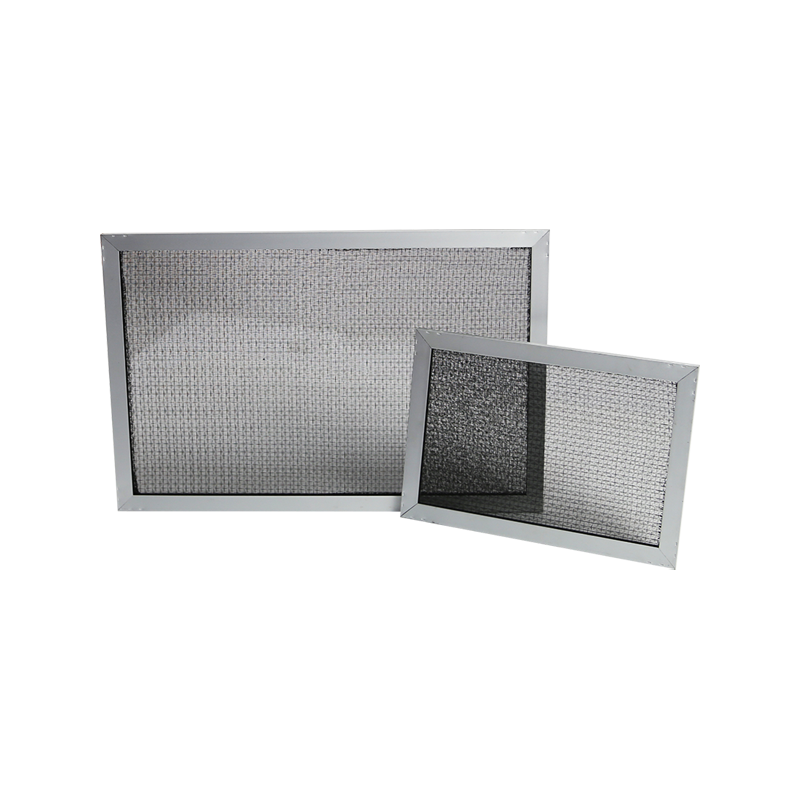

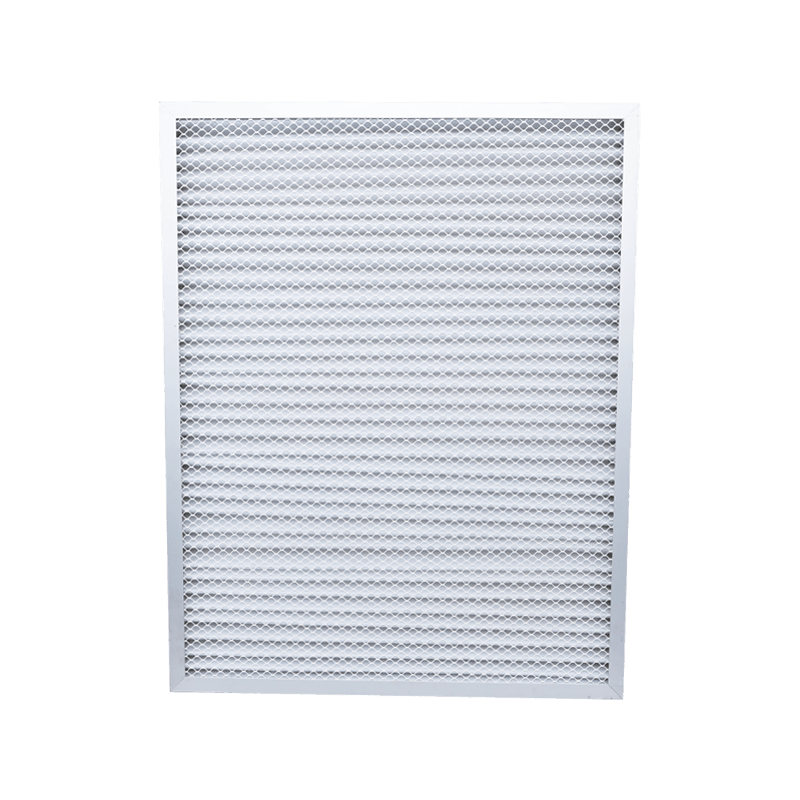

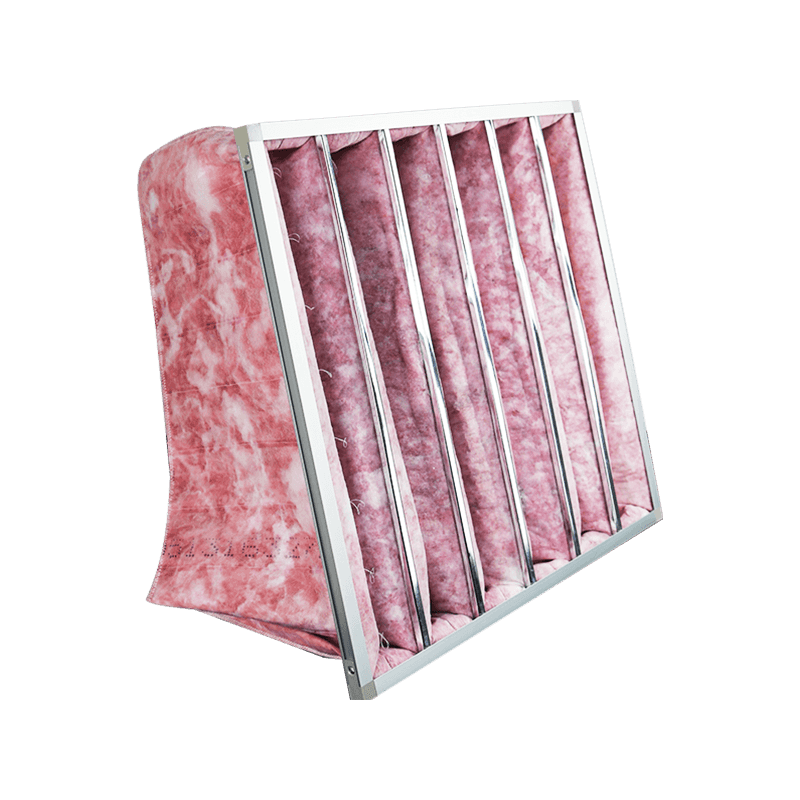

Aluminum separator air filters consist of multiple layers of aluminum mesh or aluminum foils that separate filter media, typically synthetic fibers or paper. The aluminum structure provides rigidity, resistance to corrosion, and support for high airflow rates, making these filters suitable for demanding applications.

Key characteristics of aluminum separator air filters include:

- High durability: Aluminum frames and separators resist bending, corrosion, and physical stress.

- Low resistance: Designed for minimal pressure drop while maintaining filtration efficiency.

- Reusable design: Many aluminum separator filters can be cleaned and reused multiple times.

- High-temperature tolerance: Suitable for high-temperature airflows where synthetic or paper-only filters may fail.

Understanding the structure and function of the filter helps in determining the appropriate cleaning and maintenance procedures.

2. Signs That the Filter Needs Cleaning

Proper maintenance starts with knowing when a filter requires attention. Common indicators include:

- Reduced airflow: If airflow is noticeably diminished, particulate buildup on the filter is likely.

- Visible dirt and dust: Accumulation of debris on the aluminum separator indicates the need for cleaning.

- Pressure drop: In industrial systems, a significant increase in pressure drop across the filter signals blockage.

- Unusual odors: Dust, pollen, or other particulates trapped in the filter can produce odors over time.

Monitoring these signs helps prevent equipment strain, energy inefficiency, and potential system damage.

3. Safety Precautions Before Maintenance

Before beginning cleaning or maintenance procedures, it is important to follow safety protocols:

- Turn off the system: Ensure the equipment connected to the air filter is completely powered down to prevent injury or system damage.

- Wear protective gear: Use gloves, a dust mask, and safety goggles to protect against dust, debris, and cleaning chemicals.

- Work in a well-ventilated area: Cleaning can release fine particulates, so perform the process in a space with adequate airflow or outdoors.

- Follow manufacturer guidelines: Always refer to the manufacturer’s recommendations for cleaning and replacement to avoid warranty issues.

4. Cleaning Methods for Aluminum Separator Air Filters

Aluminum separator filters are durable and can typically be cleaned using the following methods:

a) Dry Cleaning

-

Tools Needed: Soft brush, compressed air, vacuum cleaner.

-

Procedure:

- Remove the filter from its housing carefully.

- Use a soft brush to dislodge loose dust and debris from the aluminum surfaces.

- Blow compressed air through the filter from the clean side to the dirty side to push contaminants out. Keep the air pressure moderate to avoid damaging the filter media.

- Vacuum any remaining particles from the filter surface.

-

Advantages: Safe for delicate filters, avoids moisture exposure.

-

Limitations: May not remove sticky or oily residues.

b) Wet Cleaning

-

Tools Needed: Mild detergent or cleaning solution, soft brush or sponge, water.

-

Procedure:

- Remove the filter and gently rinse it under lukewarm water.

- Apply a mild detergent solution to the aluminum mesh and filter media. Avoid harsh chemicals that could corrode the aluminum.

- Use a soft brush or sponge to gently scrub areas with stubborn dirt.

- Rinse thoroughly to remove all soap residues.

- Allow the filter to air dry completely before reinstalling. Do not use heat sources such as hair dryers or ovens, as high heat can damage the filter media.

-

Advantages: Effective for removing grease, sticky dust, and other adhered particles.

-

Limitations: Requires complete drying to prevent mold growth or corrosion over time.

c) Chemical Cleaning (If Applicable)

Some industrial applications may involve filters exposed to oily or chemical-laden air. In such cases, specialized cleaning agents designed for aluminum separator filters may be used. Always check compatibility and follow safety instructions when using chemical cleaners.

5. Maintenance Tips for Longevity

Proper maintenance goes beyond cleaning. To extend the life of aluminum separator air filters, consider the following:

- Regular Inspection: Establish a routine inspection schedule based on the environment and usage. For dusty industrial sites, weekly checks may be necessary; for cleaner indoor environments, monthly inspections might suffice.

- Avoid Physical Damage: Handle filters gently to prevent bending or deforming the aluminum separators. Damaged filters lose efficiency and may require replacement.

- Prevent Corrosion: While aluminum is corrosion-resistant, prolonged exposure to moisture or harsh chemicals can still cause damage. Ensure filters are completely dry after wet cleaning.

- Rotate or Replace Filters: Even with proper care, filters have a finite lifespan. Follow manufacturer recommendations for replacement intervals to maintain system performance.

- Maintain Surrounding Equipment: Keep ductwork, fan blades, and housings clean to reduce contaminant load on the filter.

6. Benefits of Proper Maintenance

Regular maintenance and cleaning of aluminum separator air filters provide several benefits:

- Improved Airflow and System Efficiency: Clean filters reduce pressure drop, allowing fans and blowers to operate efficiently.

- Energy Savings: Reduced airflow resistance means less energy consumption, lowering operational costs.

- Extended Filter Life: Proper cleaning prevents premature deterioration and delays replacement costs.

- Enhanced Filtration Performance: A clean filter captures more dust, pollen, and particulate matter, improving indoor air quality or protecting machinery.

- Reduced Equipment Wear: Preventing particulate buildup reduces strain on downstream components such as motors, compressors, or duct systems.

7. Common Mistakes to Avoid

Even with good intentions, improper maintenance can reduce filter performance:

- Using Excessive Pressure: Compressed air that is too strong can damage the aluminum mesh or media.

- Incomplete Drying: Installing a wet filter can cause mold growth or aluminum corrosion.

- Harsh Chemicals: Strong acids or alkalis can weaken aluminum and degrade filter media.

- Neglecting Inspections: Waiting until the filter is visibly dirty may allow contaminants to bypass the filter, harming the system.

Avoiding these mistakes ensures the filter continues to perform at its best.

8. When to Replace Aluminum Separator Air Filters

Even with proper maintenance, filters eventually reach the end of their service life. Indicators that replacement is necessary include:

- Visible tears, bends, or damage to the aluminum mesh.

- Persistent airflow reduction despite thorough cleaning.

- Accumulation of stains or residues that cannot be removed.

- Manufacturer-specified service intervals have been exceeded.

Timely replacement prevents system inefficiency and potential damage to downstream equipment.

Conclusion

Aluminum separator air filters are highly durable and efficient, but their performance depends on proper maintenance and cleaning. Regular inspections, appropriate cleaning methods, and careful handling are key to extending filter life and maintaining system efficiency. Whether using dry brushing, compressed air, or wet cleaning with mild detergents, it is essential to follow manufacturer guidelines to avoid damaging the aluminum separators or filter media.

By implementing a consistent maintenance routine, industrial operators, facility managers, and homeowners can enjoy better airflow, energy savings, improved filtration, and extended filter lifespan. Ultimately, well-maintained aluminum separator air filters protect both equipment and air quality, delivering reliable performance over years of operation.

How Do Box HEPA Filters Compare to Panel and Cartridge HEPA Filters?

How Do Panel Air Filters Improve Indoor Air Quality?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文