From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

Can cylindrical filter cartridges be cleaned and reused?

In many industrial filtration systems, cylindrical filter cartridges are common core components and are widely used in many fields such as air purification, water treatment, liquid filtration, and dust removal equipment.

Which cylindrical filter cartridges can be reused?

In general, cylindrical filter cartridges made of the following materials have a certain degree of cleaning resistance and can be reused many times:

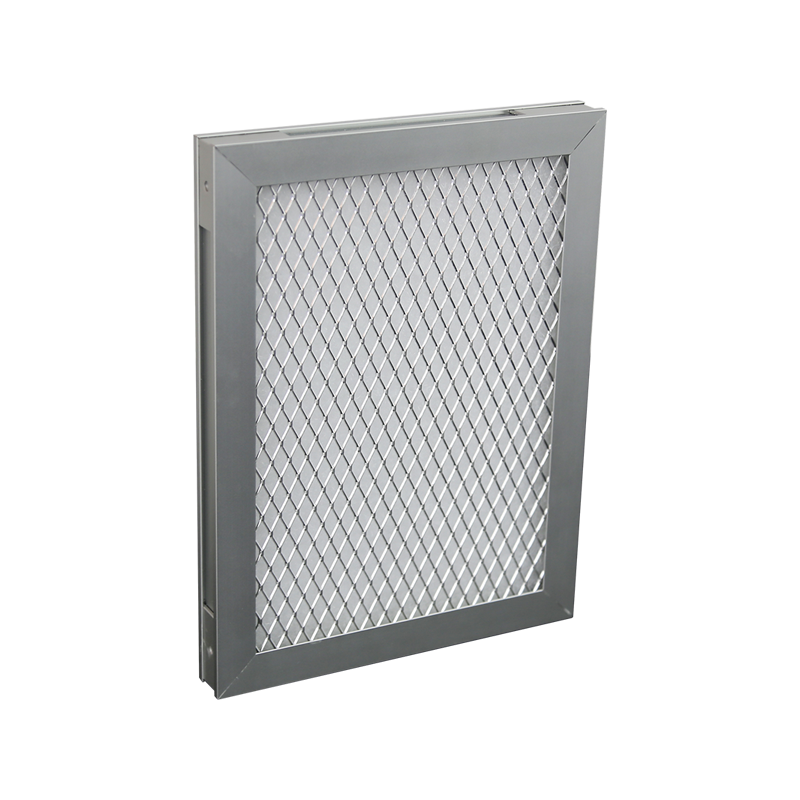

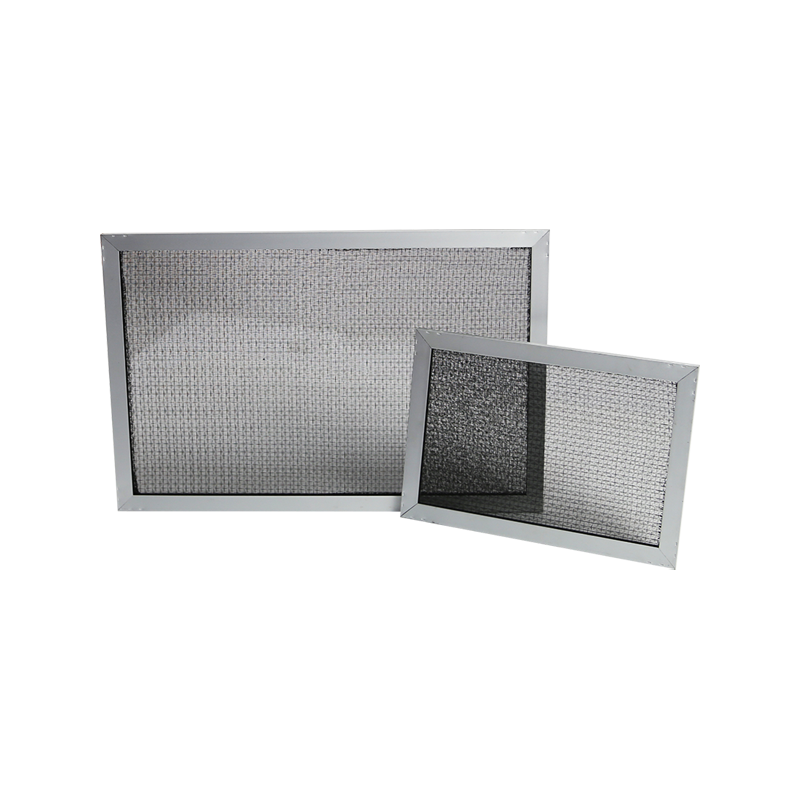

Stainless steel mesh filter cartridge: sturdy structure, can withstand high-pressure flushing, chemical cleaning and other treatments.

Sintered metal filter cartridge: uniform pore size, suitable for high temperature and high pressure occasions, long service life.

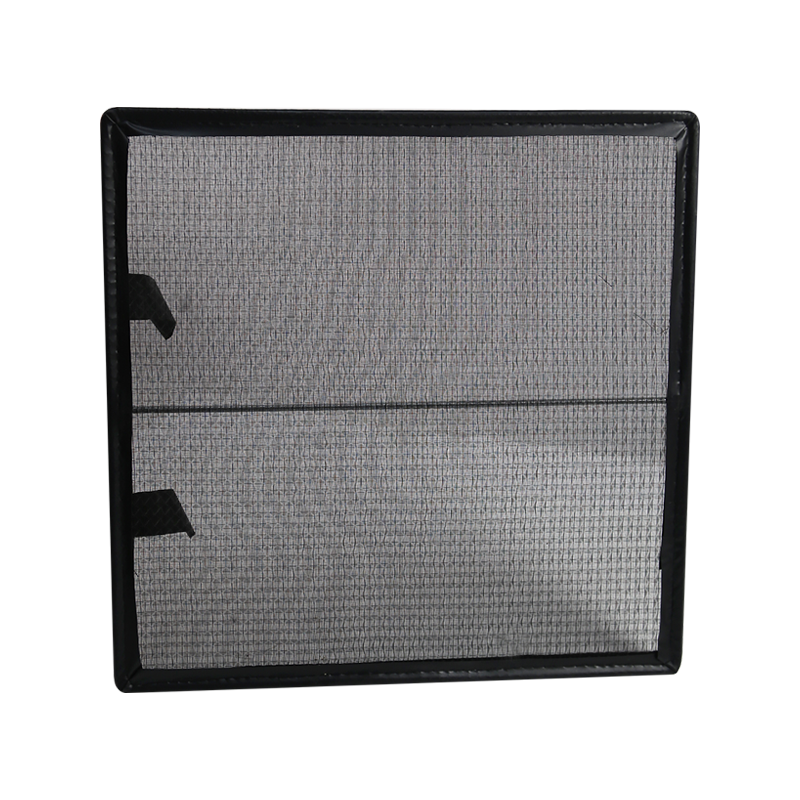

Polyester fiber or synthetic fiber filter cartridge: some have the ability to be washed and blown by wind, and are often used in dust removal systems or primary air filtration.

Which filter cartridges are not recommended for cleaning?

Although some cylindrical filter cartridges are similar in appearance, their internal structure or materials are not suitable for cleaning, for example:

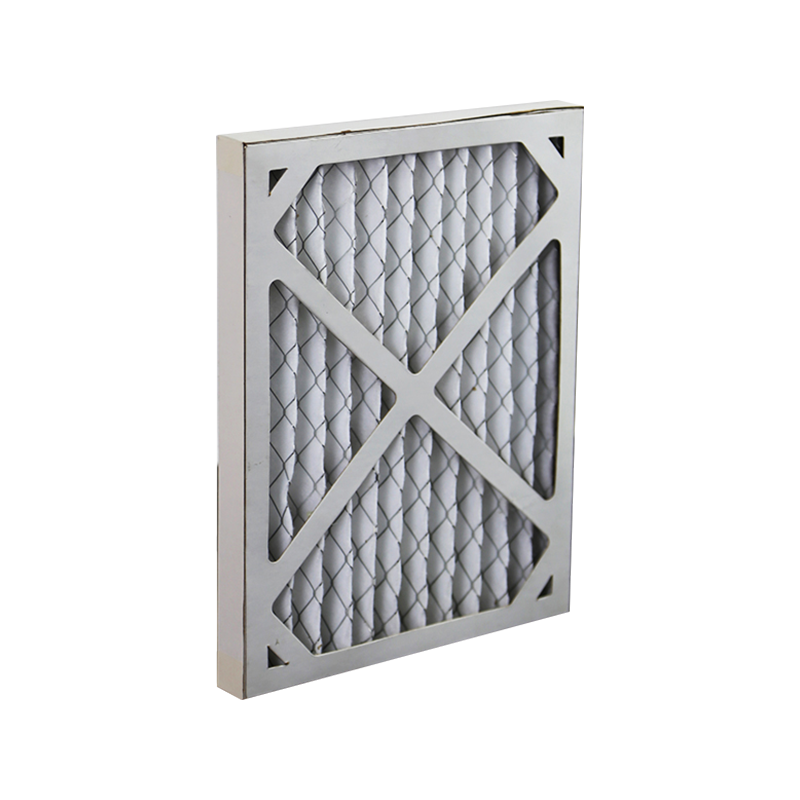

Paper or cellulose filter cartridge: commonly found in cheap liquid or air filtration equipment, strong water absorption, and easy to deform once in contact with liquid.

Meltblown PP filter element: suitable for micron-level filtration, with a dense structure, it is difficult to clean thoroughly once blocked.

High-precision filter element for pharmaceutical or clean room: extremely high requirements for hygiene and precision, usually for one-time use.

Forced cleaning in these scenarios not only fails to restore the filtering capacity of the filter element, but may also cause secondary pollution, affecting product quality and even the safe operation of the equipment.

How to clean reusable filter elements?

For washable cylindrical filter elements, the following common cleaning methods can be adopted:

Air blowing: use compressed air to blow out dust and particles inside the filter element from the opposite direction, suitable for dry dust removal occasions.

Water washing: soak the filter element in clean water or cleaning liquid, and then rinse with low-pressure water, suitable for polyester filter elements.

Chemical cleaning: use weak acid or alkaline cleaning agents to remove oil and scale layers, suitable for metal filter elements.

Ultrasonic cleaning: shake out the dirt inside the filter element through high-frequency vibration, suitable for precision metal filter elements.

Note: After each cleaning, be sure to dry the filter thoroughly before reinstalling it in the equipment to prevent residual moisture from causing mold or contamination.

Cleaning does not mean permanent use

Even washable filter elements do not have an infinite service life. Long-term use and multiple cleanings can lead to:

Damage or deformation of the filter pore structure

Decreased filtration efficiency

Weakened mechanical strength of the filter element

Accumulation of sediment that cannot be completely removed

It is generally recommended to replace it after 3 to 10 cleanings, depending on the manufacturer's recommendations or the operation of the equipment.

Whether it can be cleaned and reused depends on specific issues

Whether the cylindrical filter element can be cleaned and reused depends on the following points:

Whether the material is resistant to cleaning (such as metal, polyester)

Whether the use environment allows reuse (whether it is clean or has high hygiene standards)

Type of pollutants in the filter element (granular or sticky pollutants)

Whether the cleaning method is appropriate and effective

For general industrial or commercial purposes, using a filter element made of washable material and performing reasonable cleaning management is an economical, environmentally friendly and practical way. However, for high-precision or disposable filter elements, they should be replaced in a timely manner as required to avoid losing more than less.

Can HEPA Filters Be Washed or Reused Safely?

Mini Pleated HEPA Air Filters: A miniature weapon for efficient purification

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文