From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

How often should you replace primary air filter?

Introduction: Why replacement frequency matters

Primary air filters (also called pre-filters or coarse filters) protect HVAC systems and downstream high-efficiency filters by capturing large particulates such as dust, lint, pollen and debris. Replacing them at the right interval preserves indoor air quality, reduces energy use, extends the life of secondary filters and protects fan motors and heat exchangers from dust buildup. This article gives practical, actionable guidance on how often you should replace primary air filters across residential, commercial and industrial settings, and how to tailor a schedule based on operating conditions and filter type.

Key factors that determine replacement intervals

No single calendar interval fits every situation. Replacement frequency depends on a combination of filter type, airflow rates, system runtime, local air quality, occupancy, and the presence of pollution sources (construction, cooking smoke, industrial emissions). Higher dust loads, continuous operation, and environments with airborne contaminants shorten filter life. Conversely, seasonal or intermittent use and clean environments allow longer intervals. Always use a condition-based approach rather than relying solely on a fixed calendar period.

Operational variables to consider

Consider runtime (hours per day), average airflow (m³/h or CFM), relative humidity, and whether the system uses supplemental filtration (HEPA, electrostatic). Systems that run 24/7 in dusty environments will need more frequent replacement than a residential furnace running a few hours daily during winter. Also account for activities that periodically spike particulate loads such as renovations or heavy traffic nearby.

Replacement guidance by filter type

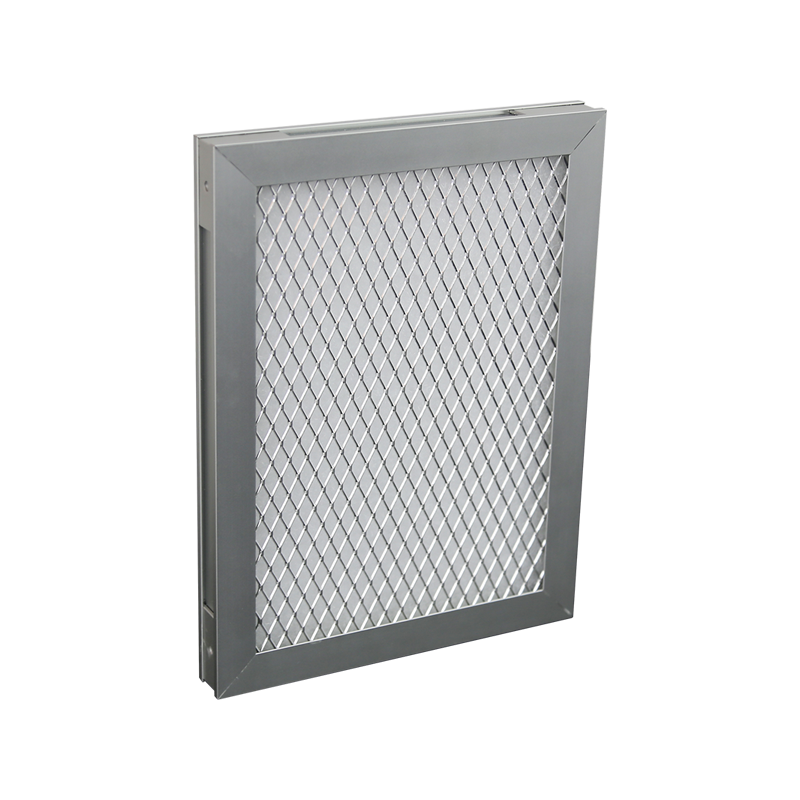

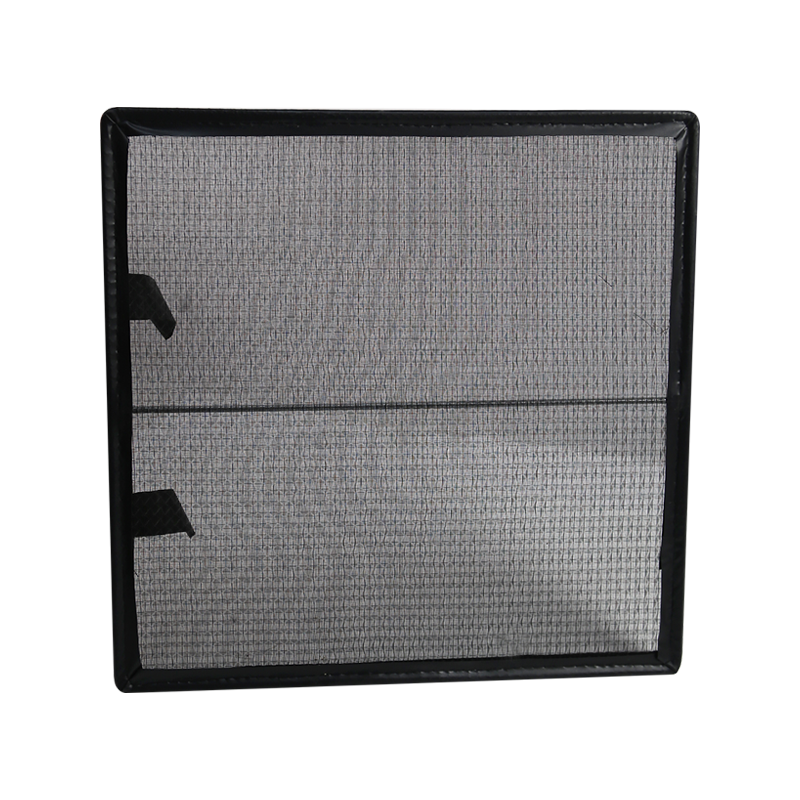

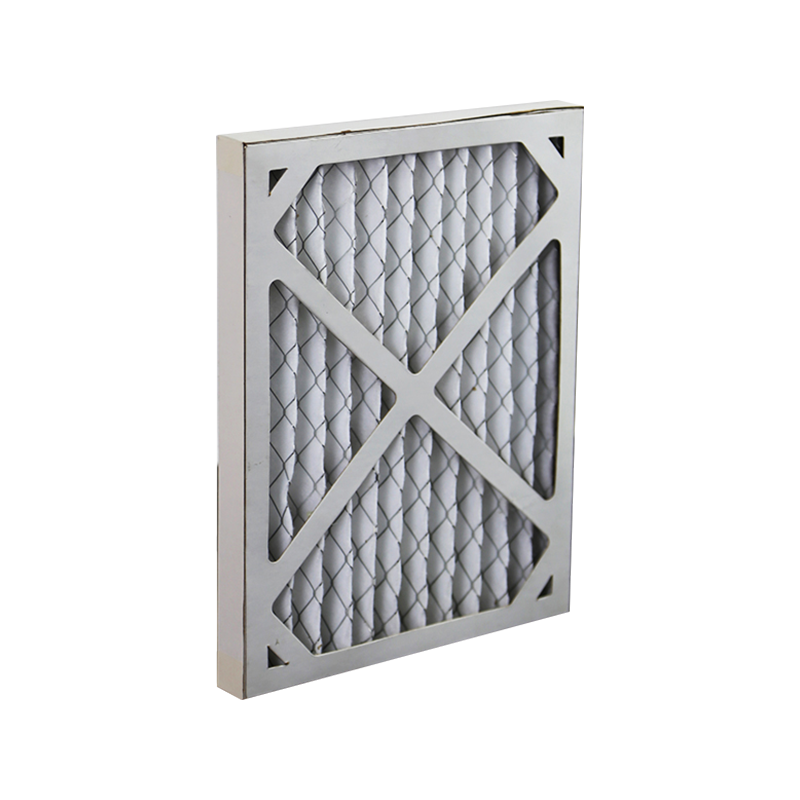

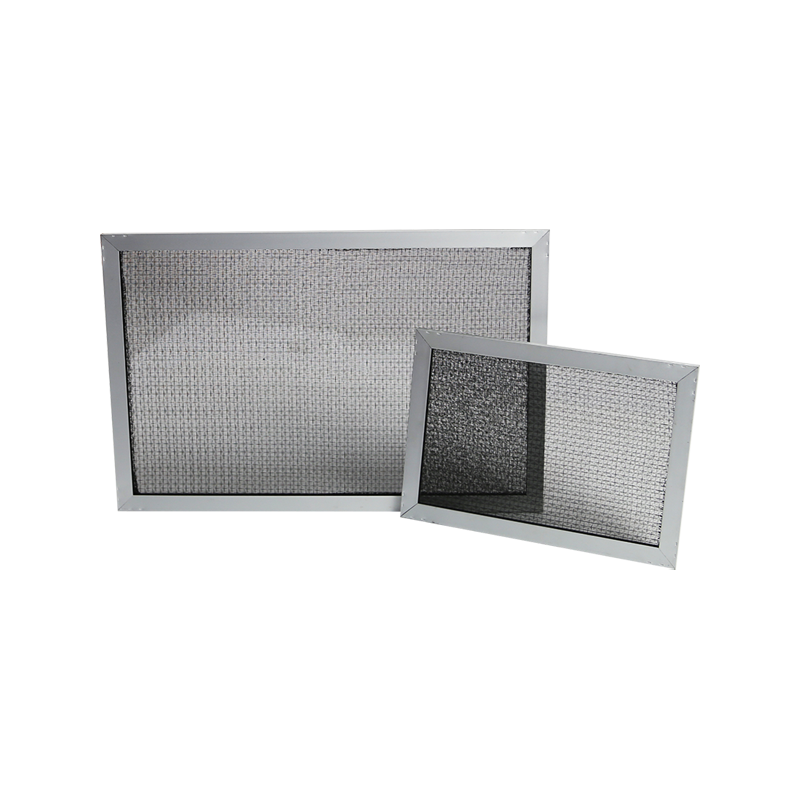

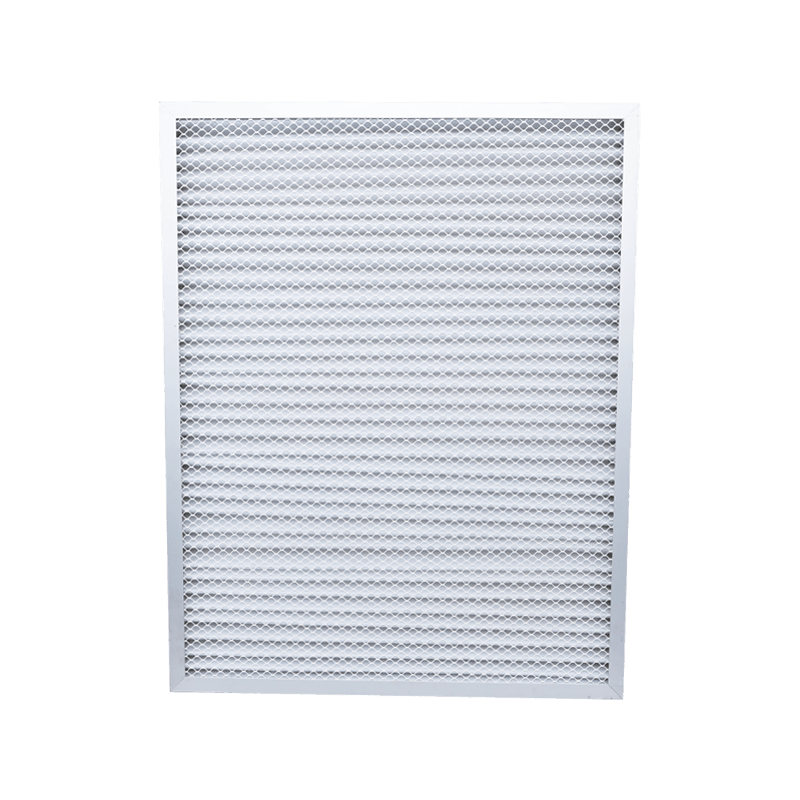

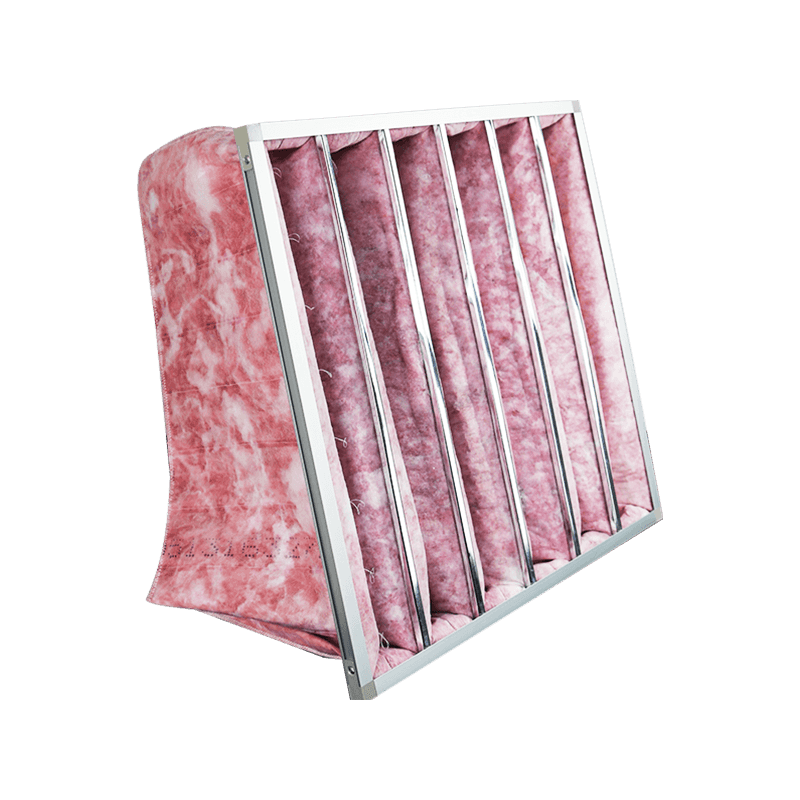

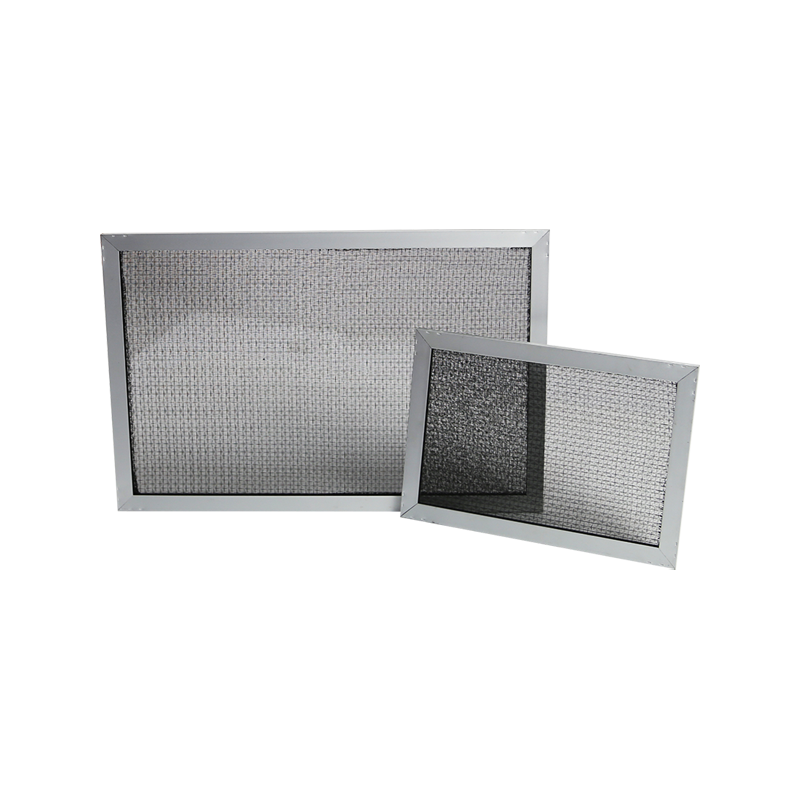

Primary filters come in various media and frames: pleated synthetic, fiberglass panels, washable metal or synthetic meshes, and pocket (bag) filters rated to low efficiencies (G1–G4 in EN779 or MERV 1–4 equivalents). Below are practical intervals for typical scenarios — treat them as starting points and adjust based on inspection and performance.

- Fiberglass disposable panel filters (low-efficiency): replace every 30–90 days in residential use; in dusty or high-use commercial sites replace every 30 days.

- Pleated synthetic panel filters (higher dust-holding capacity): replace every 60–180 days in homes; every 30–90 days in commercial applications depending on load.

- Washable/reusable metal or synthetic screens: inspect monthly and clean when visibly dirty; longevity is multi-year but cleaning regimens must be strict to avoid pressure drop.

- Pocket/bag primary filters used in AHUs: replace every 3–12 months depending on airflow and dust load; high-traffic public buildings often replace quarterly.

Inspection and monitoring to move beyond fixed schedules

Condition-based replacement is more efficient and safer than arbitrary time intervals. Implement scheduled visual inspections, pressure-drop monitoring and simple in-situ tests to know when a filter needs replacement. Modern facilities often use differential pressure gauges or sensors across the filter bank; when pressure drop reaches the manufacturer's recommended limit (or a predefined percentage above clean condition), it’s time to change filters.

Practical inspection steps

Turn the unit off or isolate it per safety procedures before inspecting. For panel filters, remove and hold them up to a light source — if light penetration is minimal or dust cake is uniform, replace. For washable filters, check for oil or sticky deposits that water cannot remove; these require replacement or specialist cleaning. For AHUs, record clean and in-use differential pressures to build an evidence-based replacement trigger.

Comparison table: typical replacement intervals

| Filter Type | Residential Typical | Commercial / AHU Typical |

| Fiberglass disposable | 30–90 days | 30–60 days |

| Pleated synthetic | 60–180 days | 30–90 days |

| Washable / metal screen | Clean monthly as needed | Clean monthly; replace if damaged |

| Pocket / bag filters | Not typical | 3–12 months |

Signs you must replace immediately

Certain symptoms require immediate action: visible clogging causing poor airflow, an abrupt rise in differential pressure, odors or mold growth on the filter, water or oily contamination that traps particulates, or upstream/downstream temperature changes suggesting heat-exchanger fouling. In HVAC systems, if occupants complain of poor ventilation or IAQ issues coincide with filter age, replace promptly and investigate root causes.

Practical tips for extending filter life safely

You can extend filter life without compromising safety by implementing pre-filtration (a coarse grid ahead of the primary filter), practicing good housekeeping (minimizing indoor dust sources), scheduling regular inspections, and using higher dust-holding capacity pleated media for the primary stage. However, do not overextend life beyond pressure-drop recommendations — doing so reduces airflow, strains fans and risks bypass or particle re-entrainment.

- Record differential pressure at clean-install and set a maximum allowable limit for replacement.

- Use filter tracking logs or CMMS entries for large facilities to avoid missed changes.

- Choose filters with higher dust-holding capacity if change intervals are difficult to maintain.

Environmental and cost considerations

Frequent replacement increases waste and cost, while delayed replacement raises energy use and equipment wear. Balance lifecycle cost (filter price, fan energy, maintenance labor) and environmental impact by selecting durable media, using reusable pre-filters where practical, and ensuring proper disposal or recycling programs. Bulk purchasing and scheduled maintenance reduce per-change cost and logistic overhead.

Conclusion: move to a condition-based schedule

Rather than a one-size-fits-all calendar interval, use a condition-based replacement strategy: choose initial intervals by filter type and application, monitor pressure drop and visual condition, and adapt the schedule based on observed dirt-loading and operating context. For homes, start with 30–90 days for simple panels and 60–180 days for pleated filters; for commercial AHUs, rely on differential pressure and quarterly inspections with more frequent changes under heavy loads. Prioritize occupant health, energy efficiency and equipment longevity when deciding replacement frequency.

How Do Panel Air Filters Compare to Other Types of Air Filters?

How to Choose the Right Box HEPA Filter for Your Air Purifier or HVAC System?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文