How do airline/subway air filters improve passenger satisfaction?Airline/subway air filters improve passenger satisfaction by:

1. Improve air quality: By effectively removing pollutants, bacteria, viruses and allergens from the air, air filters can significantly improve the breathing experience of passengers, making them feel more comfortable.

2. Reduce odors: Activated carbon filters can remove odors in the cabin, such as tobacco, food and other unpleasant odors, providing passengers with fresher air quality.

3. Increase passengers’ sense of security: During flu season or epidemics, efficient air filtration systems can increase passengers’ confidence in the hygienic conditions of transportation and reduce their worries about infection.

4. Reduce allergic reactions: For passengers with allergies, air filters can reduce exposure to allergens and reduce the risk of allergic reactions.

5. Improved comfort: Good air quality improves the overall comfort of passengers, making their journeys more enjoyable.

6. Energy Saving and Environmental Protection: By improving the efficiency of air conditioning and ventilation systems, air filters help reduce energy consumption, which can improve passengers' perception of airlines or metro operators' environmental practices.

7. Transparency and communication: Communicating information about the air filtration system to passengers, such as filter type, replacement intervals and maintenance schedules, can increase passenger trust in the operator.

8. Personalized controls: Where possible, providing passengers with control over air flow and temperature can increase their satisfaction.

How do aviation/subway air filters reduce energy waste?Airline and subway air filters can reduce energy waste by:

1. Use energy-saving technology: Consider using energy-saving technology, such as solar or wind power, to provide some energy for your air filtration system.

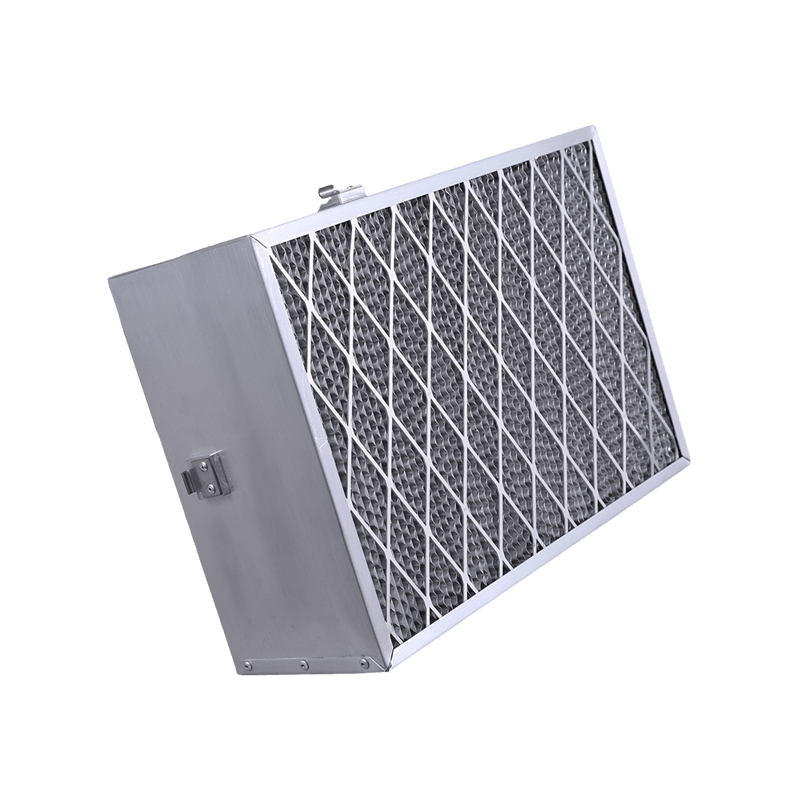

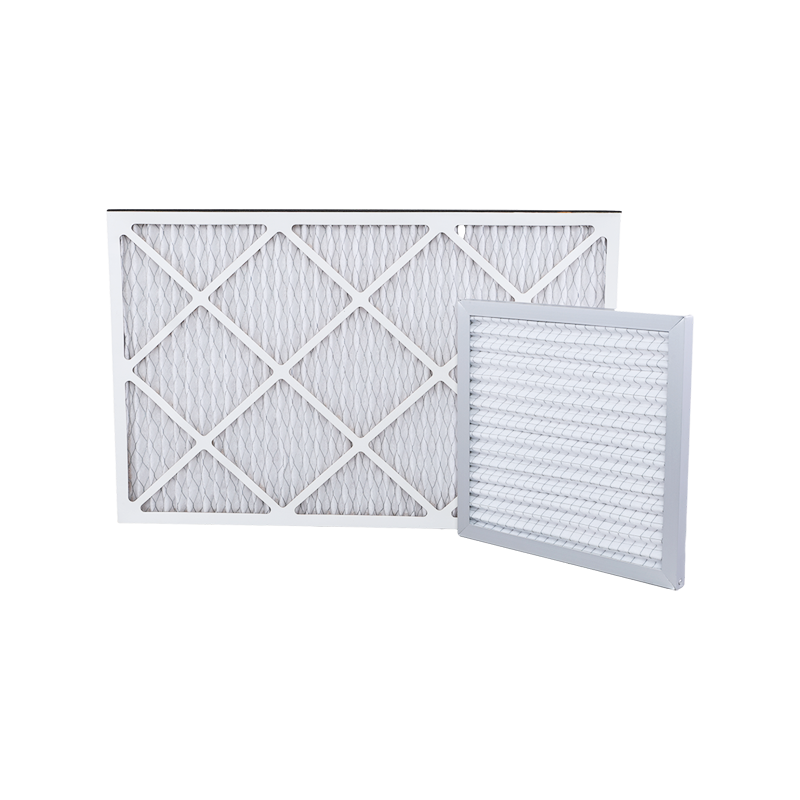

2. Choose the right filter: Use a filter that is appropriate for your specific environment and needs. For example, using HEPA filters can more effectively remove particulate matter from the air and reduce the burden on the air conditioning system.

3. Optimize system design: Design an efficient air filtration system to minimize energy consumption. For example, a variable frequency drive (VFD) can be used to adjust the speed of a fan to suit different air flow needs.

4. Sensor integration: Integrate air filters with sensors to monitor air quality and system performance. Sensors can automatically adjust the operation of fans and air conditioners based on air quality, reducing energy waste.

5. Reduce air recirculation: Where possible, reduce the need for air recirculation. The introduction of fresh air can reduce the need for air filtration and treatment, thereby reducing energy consumption.

6. Energy-saving mode: During off-peak hours or when there are fewer passengers, use energy-saving mode to reduce the operating speed of the air filtration system.

7. Zoning controls: Where possible, use zoning controls to regulate the operation of the air filtration system based on passenger density. This avoids wasting energy in open areas.

8. Energy efficiency standards: Follow energy efficiency standards and regulations and choose energy-saving equipment and systems.

9. Reduce system leakage: Ensure the air filtration system is well sealed to reduce air leakage, which can reduce energy waste and improve filtration efficiency.

.

English

English русский

русский Español

Español