In what aspects is the durability of the cylindrical filter reflected?The durability of the

cylindrical filter is reflected in the following aspects:

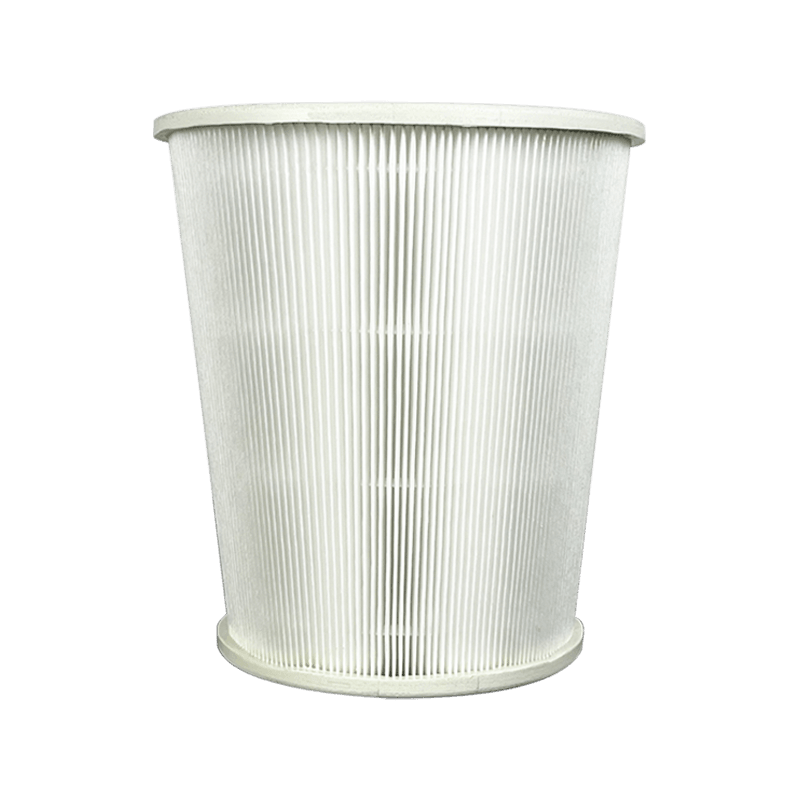

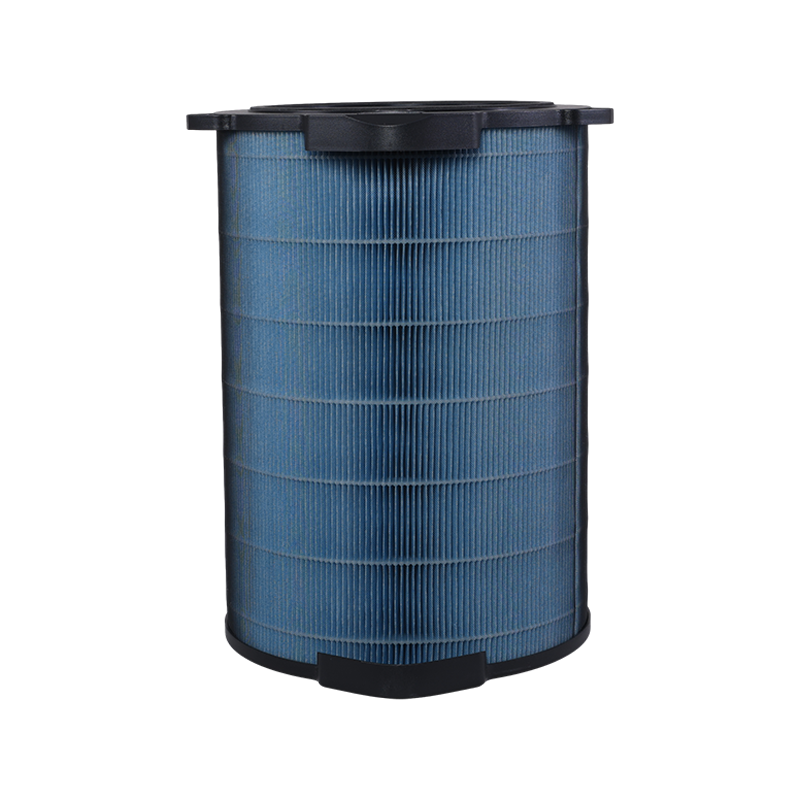

1. Structural design: The cylindrical design provides uniform stress distribution, helping to improve the stability and durability of the filter.

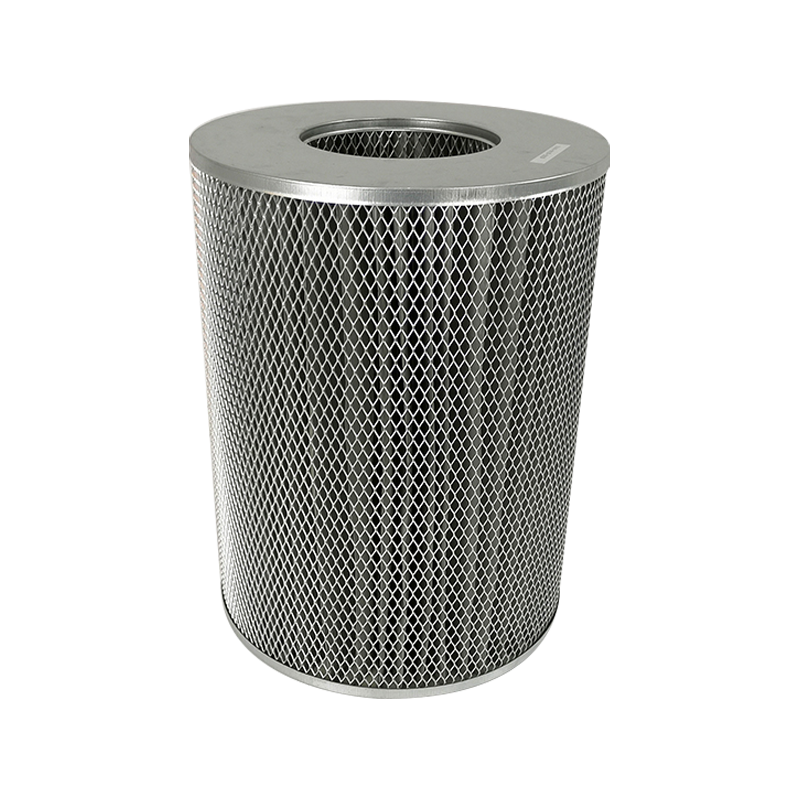

2. Material selection: Cylindrical filters are usually made of high-quality materials, such as stainless steel, plastic, special fibers or metal mesh, which have good wear resistance, corrosion resistance and temperature resistance.

3. Resistance to clogging: The design of the cylindrical filter helps reduce the risk of clogging, thereby extending its service life.

4. Easy to maintain: Many cylindrical filters are designed with replaceable filter elements, making maintenance and cleaning simple, helping to maintain filter performance and extend service life.

5. Strong adaptability: Cylindrical filters can be designed to adapt to different working environments, such as high pressure, high temperature or high pollution environments, thereby improving their durability.

6. Customizability: According to specific application requirements, cylindrical filters can be customized with different filter materials, pore sizes and filtration precision to meet durability requirements under different working conditions.

7. Chemical Resistance: Some cylindrical filters are made with chemical-resistant materials, allowing them to maintain performance and durability in harsh chemical environments.

8. Mechanical strength: The structure of the cylindrical filter usually has high mechanical strength and can withstand high working pressure and impact load.

9. Impact resistance: The design and material selection of the cylindrical filter can improve its impact resistance and reduce damage caused by accidental impact or vibration.

10. Long-term stability: The cylindrical filter can maintain stable filtration performance during long-term use and is not prone to performance degradation or failure.

11. Economical: Although the initial investment of a cylindrical filter may be higher, its durability and long life can reduce long-term operating costs.

12. Quality control: Manufacturers usually conduct strict quality control on cylindrical filters to ensure that they meet high standards of durability during the production process.

In what aspects is the cylindrical filter easy to maintain?The easy maintenance features of

cylindrical filters are reflected in the following aspects:

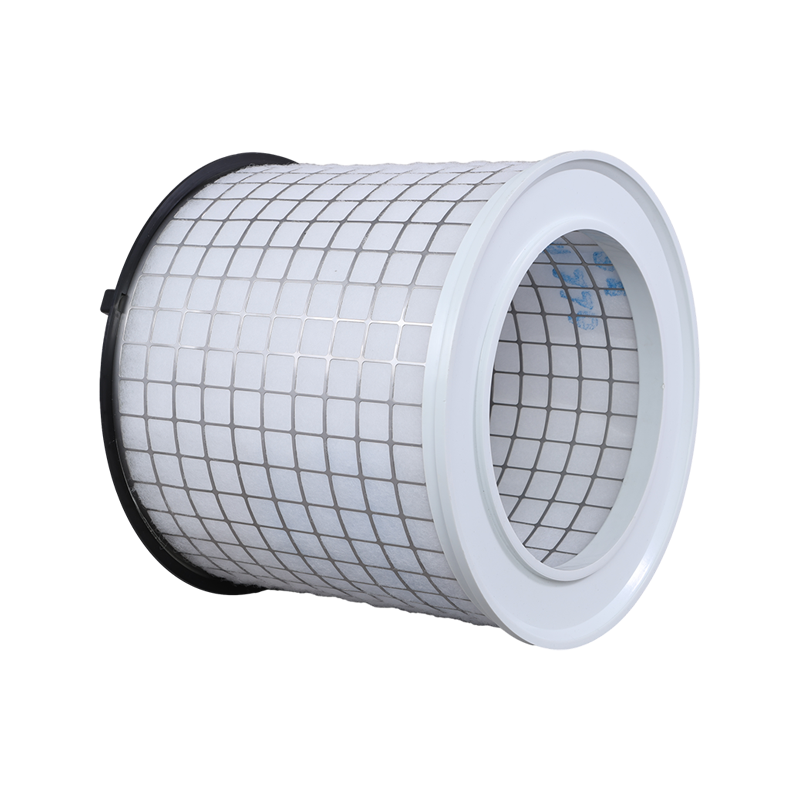

1. Simple structure: The design of cylindrical filters is usually relatively simple and easy to understand and operate, making maintenance work more intuitive and convenient.

2. Replaceable filter element: Many cylindrical filters adopt a replaceable filter element design. When the filter element needs to be replaced, users only need to replace the filter element instead of the entire filter, reducing maintenance costs.

3. Easy to disassemble: The disassembly and assembly process of cylindrical filters is usually simple and does not require complex tools or expertise.

4. Easy to clean: The surface and internal structure design of the cylindrical filter facilitates easy cleaning. Blockages and impurities can be easily removed using water, detergent or compressed air.

5. Maintenance cycle: The maintenance cycle of the cylindrical filter can be adjusted according to actual usage and manufacturer's recommendations, and users can perform regular maintenance as needed.

6. Maintenance cost: Due to the simple structure of the cylindrical filter and the easy replacement of the filter element, its maintenance cost is relatively low.

7. Maintenance guidance: Many cylindrical filter manufacturers provide detailed maintenance guides and operating manuals to help users understand how to properly maintain and clean the filter.

8. Easy to check: The design of the cylindrical filter allows users to easily check the status of the filter, such as observing whether there are signs of clogging, damage or wear.

9. Preventive Maintenance: The design and construction of the cylindrical filter facilitates the implementation of a preventive maintenance program to ensure that the filter is operating at its best.

10. Accessories and Support: Many cylindrical filter manufacturers offer easily accessible accessories and technical support so users can get help quickly when needed.

11. Self-diagnostic function: Some advanced cylindrical filters may be equipped with a self-diagnostic function that monitors the status of the filter and alerts the user when maintenance is required.

12. Strong adaptability: The design of the cylindrical filter enables it to adapt to different maintenance environments and conditions, such as high pressure, high temperature or high pollution environments.

English

English русский

русский Español

Español